Features WGTR back up rollers

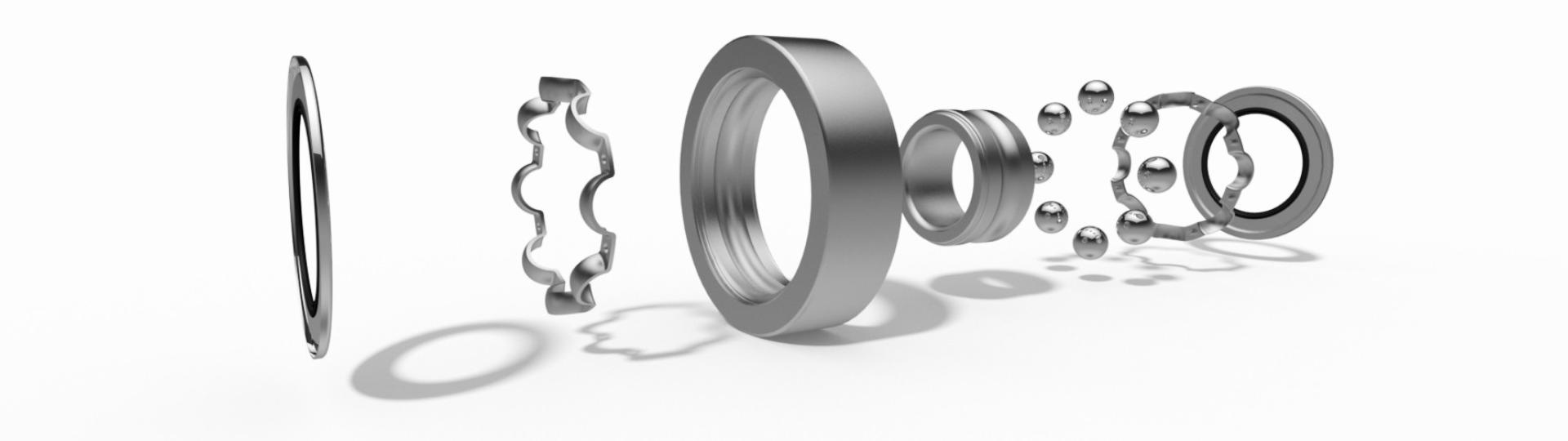

WGTR yoke type track rollers double row or multi-row rolling bearings consisting of a thick-walled, usually profiled outer ring and cylindrical rolling elements (cylindrical rollers). The outer rings generally have at least two fixed ribs, while the inner rings are usually ribless. WGTR yoke type track rollers are fitted with loose thrust washers. They can support high radial loads and low axial loads. Due to their special design, the choice of materials and the very accurate overall height, WGTR yoke type track rollers are used in the mills of multiple rolling mills. The relubrication can be optionally via holes in the inner ring.

Loads

The WGTR back-up rollers are designed for the extremely high loads in rolling operations.

Accuracies

The WGTR yoke type track rollers are manufactured with narrowed dimensional and running tolerances. By grouping in heights of 0.005 mm, the smallest height differences between the yoke type track rollers of a row are achieved.

Sealing

Typically, the WGTR back-up rollers are designed for permanent lubrication. The Seals are designed to allow the lubricant to circulate without reducing the sealing effect. For this purpose, among other things, laminar sealing rings are used, which run in a labyrinth.

Cages

WGTR back-up rollers are usually equipped with brass cages .

Materials

The outer rings of WGTR back-up rollers are made of special case hardening steels, shell hardeners, or rolling bearing steel to meet the requirements of the rolling process.

Your contact person

-

Roller bearings sales

-

+49 (2053) 497 - 36

-

Roler bearings

-

+49 (2053) 497 - 0

-

Opening hoursMo-Do.: 08:00 - 16:00

Fr.: 08:00 - 14:45

-

Delivery timesMo-Do.: 06:00 - 13:30

Fr.: 06:00 - 11:00

oder nach Absprache