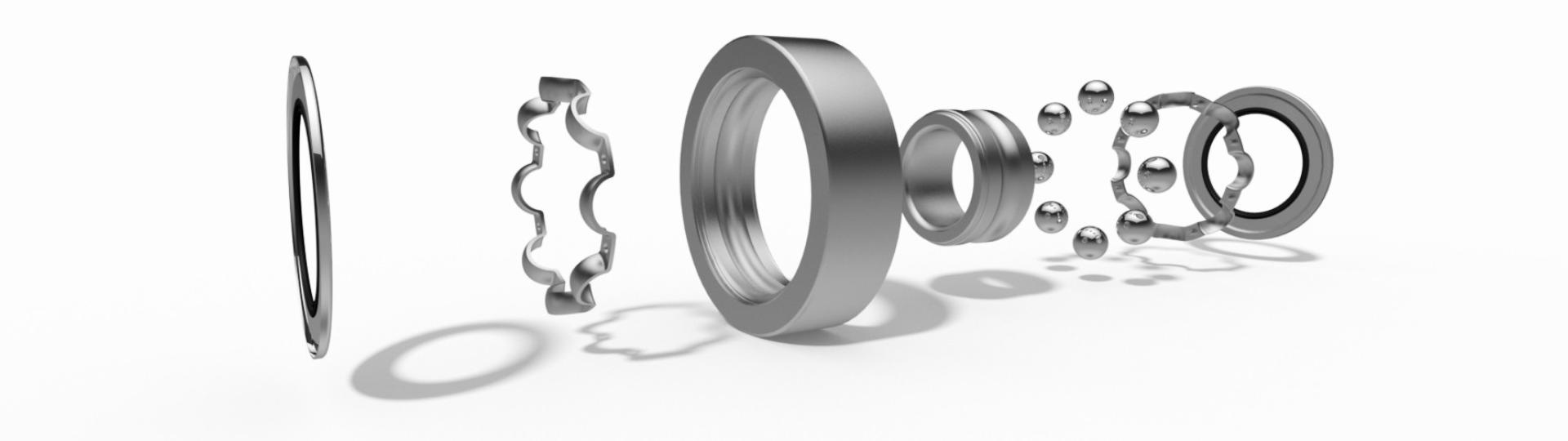

Features profile track rollers

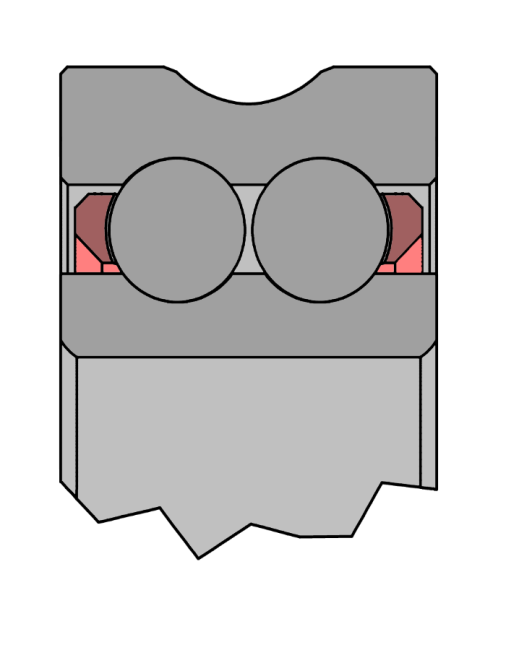

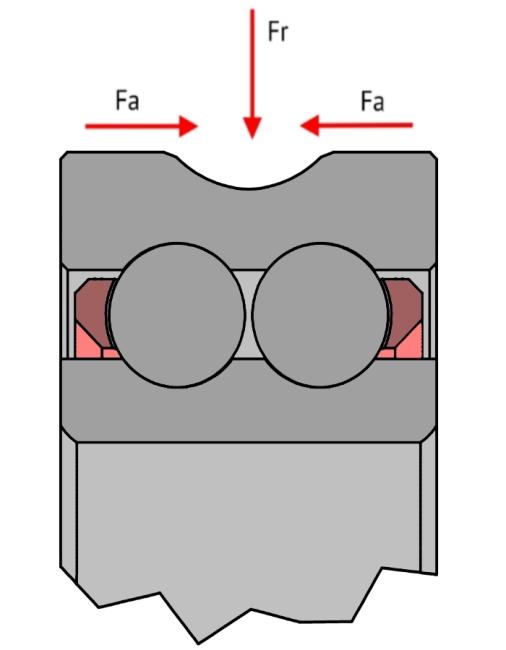

Profile track rollers correspond to double-row angular contact ball bearings in their internal design and have a thick-walled profiled outer ring. Optionally, they can be equipped with a combined inner ring bolt. The inner ring bolt can be designed eccentrically to set the stud type track roller against the raceway. They can support radial loads as well as axial loads and are suitable for guideways. The relubrication can be optionally via holes in the inner ring or a relubrication channel in the inner ring bolt.

Loads

The permissible radial load Fr zul of the track roller must not be exceeded, since the resulting pressures in contact can damage the mating track. Our service team will be pleased to provide you with information on the values for the permissible radial load capacity of the track rollers.

A ratio of Fr/Cr>0.01 is recommended for the minimum radial load capacity of track rollers. The values for the dynamic load rating Cr can be found in our product data sheets.

Accuracy

The dimensional and running tolerances of the profile track rollers normally correspond to the tolerance class P0 according to DIN 620-2. Deviating is the diameter tolerance of the crowned outer ring (tolerance field 0 to -0.05) and the tolerance of the fit on the bolt (tolerance field h7).

Bearing clearance

The profiled track rollers are designed in the standard with the bearing clearance class CN according to DIN 620-4.

| Bore diameter | C2 | CN | C3 | C4 | |||||

| over | to | min. [μm] | max. [μm] | min. [μm] | max. [μm] | min. [μm] | max. [μm] | min. [μm] | max. [μm] |

| 6 | 10 | 0 | 7 | 2 | 13 | 8 | 23 | 14 | 29 |

| 10 | 18 | 0 | 9 | 3 | 18 | 11 | 25 | 18 | 33 |

| 18 | 24 | 0 | 10 | 5 | 20 | 13 | 28 | 20 | 36 |

| 24 | 30 | 1 | 11 | 5 | 20 | 13 | 28 | 23 | 41 |

| 30 | 40 | 1 | 11 | 6 | 20 | 15 | 33 | 28 | 46 |

| 40 | 50 | 1 | 11 | 6 | 23 | 18 | 36 | 30 | 51 |

| 50 | 65 | 1 | 15 | 8 | 28 | 23 | 43 | 38 | 61 |

| 65 | 80 | 1 | 15 | 10 | 30 | 25 | 51 | 46 | 71 |

| 80 | 100 | 1 | 18 | 12 | 36 | 30 | |||

Sealing

Profiling reels are usually equipped with dust covers or RSR-.Sealing discs executed. Depending on the installation space, Sealing systems are also possible.

Cages

Profile reels are usually equipped with Plastic cages, metal cages can be used at elevated temperatures.

Materials

The profile rollers are made in your standard version from the material 1.3505 (100Cr6) and manufactured with a minimum hardness of 58 HRC. On request, corrosion protected versions are available.

Your contact person

-

Roller bearings sales

-

+49 (2053) 497 - 36

-

Roler bearings

-

+49 (2053) 497 - 0

-

Opening hoursMo-Do.: 08:00 - 16:00

Fr.: 08:00 - 14:45

-

Delivery timesMo-Do.: 06:00 - 13:30

Fr.: 06:00 - 11:00

oder nach Absprache