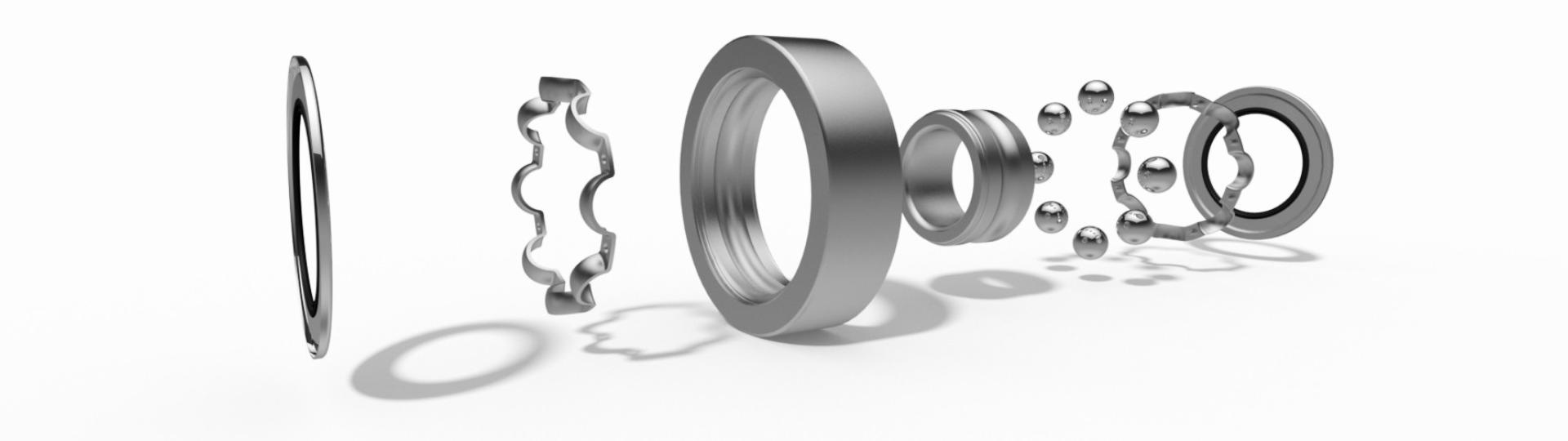

Characteristics of drawn cup needle roller and cage assemblies

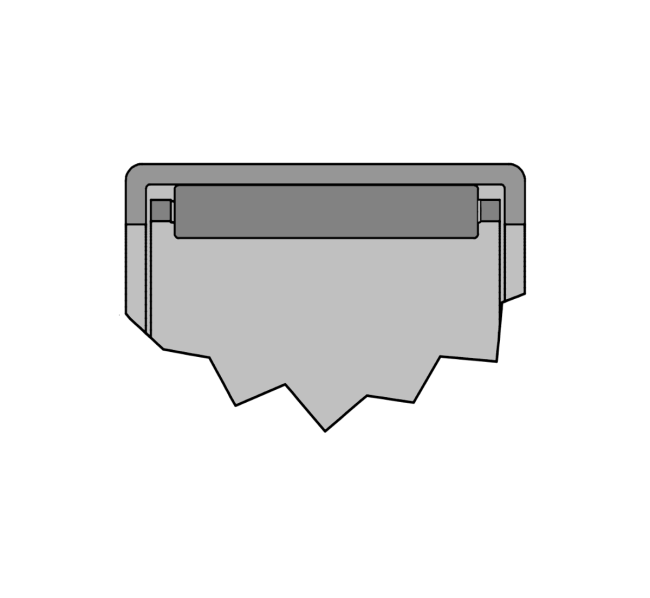

Ferrules are needle roller and cage assemblies which generally consist of a unit of drawn cup, thin-walled drawn cup needle roller and cage assemblies. Due to their design, drawn cup needle roller bearings allow high load carrying capacity in the smallest radial installation space. For applications with increased requirements for radial load carrying capacity, drawn cup needle roller and cage assemblies can also be designed with full needles.

The design of the drawn cup needle roller and cage assembly requires a hardened and ground raceway on the shaft, or the use of a separate inner ring. For mounting directly on the shaft, a minimum surface hardness of the shaft of 670 HV with sufficient hardening depth (SHD/CHD) is recommended.

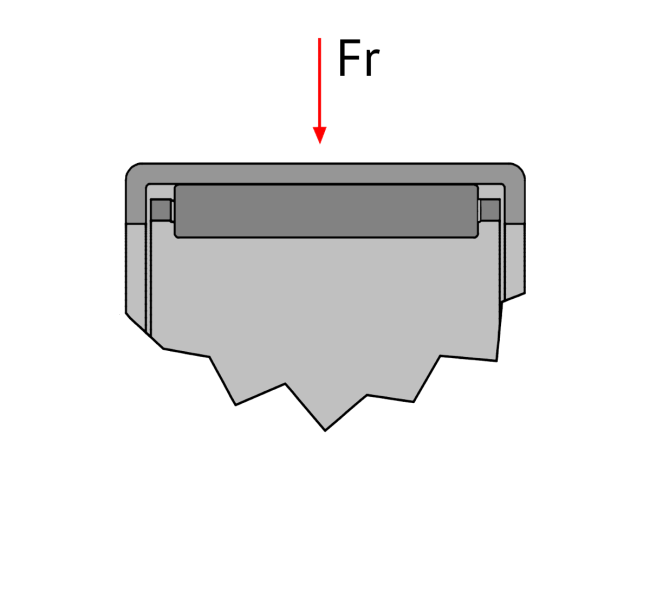

Loads

Our service team will be happy to provide you with information on the values for the load capacity of the drawn cup needle roller bearings.

Accuracies

The dimensional and running tolerances of the drawn cup needle roller bearings normally correspond to tolerance class P0 according to DIN 620-2.

Bearing clearance

The bearing clearance of the drawn cup needle roller bearings results from the adjacent construction. For more information on the design of the adjacent construction, our service team will be happy to provide you with information.

Cages

Pin-sleeves can be supplied with Plastic or metal cages can be equipped.

Materials

The rolling elements of the drawn cup needle roller bearings are made in your standard version from the material 1.3505 (100Cr6) and manufactured with a minimum hardness of 58 HRC.

Your contact person

-

Roller bearings sales

-

+49 (2053) 497 - 36

-

Roler bearings

-

+49 (2053) 497 - 0

-

Opening hoursMo-Do.: 08:00 - 16:00

Fr.: 08:00 - 14:45

-

Delivery timesMo-Do.: 06:00 - 13:30

Fr.: 06:00 - 11:00

oder nach Absprache