Cylindrical roller bearing features

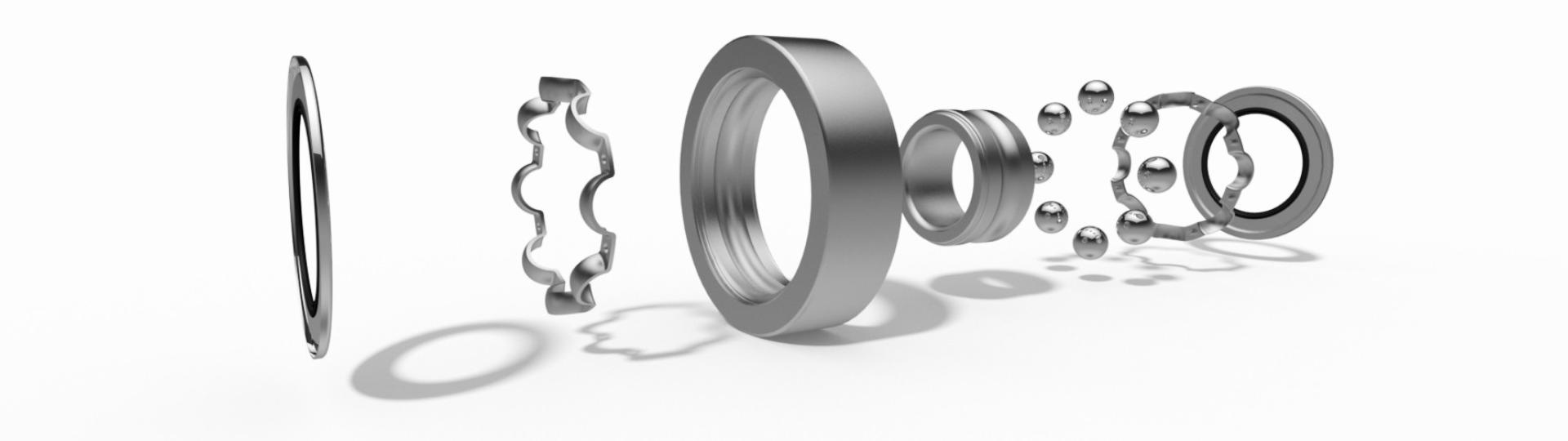

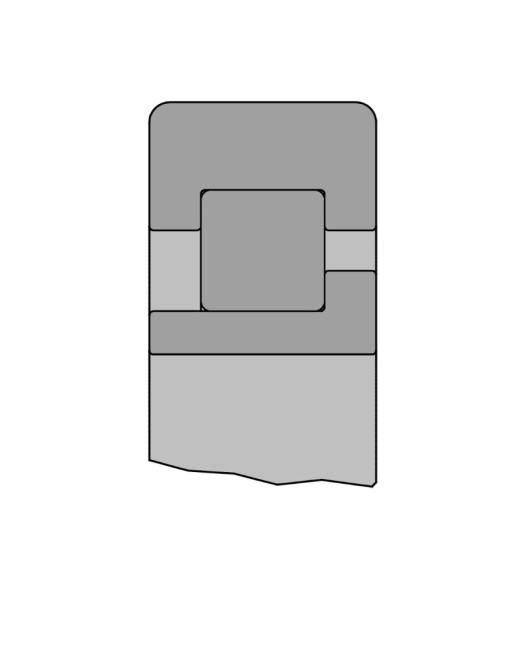

Cylindrical roller bearings are single- or double-row rolling bearings consisting of thick-walled machined bearing rings. The outer rings usually have two fixed ribs, while the inner rings are usually ribless or have one fixed rib. In addition, the cylindrical roller bearings can be equipped with loose thrust washers.

Loadability

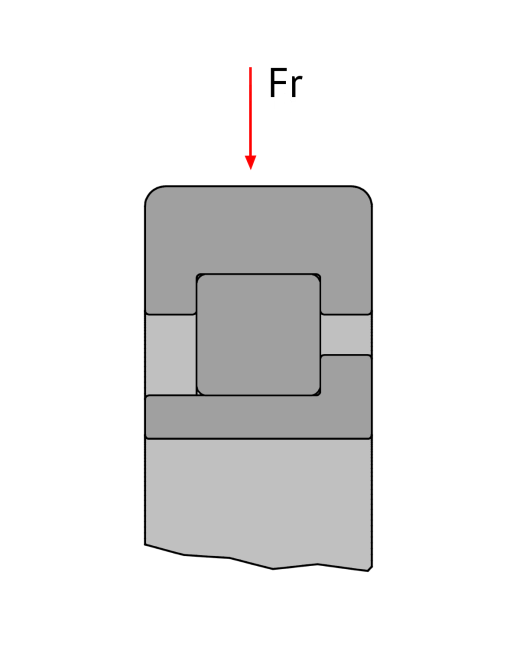

Cylindrical roller bearings are radially very high loadable and very stiff due to their mostly full complement design. For high speeds, cylindrical roller bearings with solid window cages are suitable, which prevent mutual contact of the rolling elements during rolling.

The axial load carrying capacity of cylindrical roller bearings is influenced by the design, the lubricant used and the bearing tilting. Loaded ribs or thrust washers must be supported over the entire height. The Fa/Fr ratio should not exceed 0.4. An exclusive axial load without radial load is not permissible.

For the minimum radial load of cylindrical roller bearings, a ratio of Fr/Cr>0.016 is recommended. The values for the dynamic load rating Cr can be found in our product data sheets.

Accuracy

The dimensional and running tolerances correspond to the tolerance class PN according to DIN 620-2.

Bearing Clearance

The cylindrical roller bearings are designed in the standard with the bearing clearance class C2 according to DIN 620-4.

| Bore diameter | C2 | CN | C3 | C4 | |||||

| over | to | min. [μm] | max. [μm] | min. [μm] | max. [μm] | min. [μm] | max. [μm] | min. [μm] | max. [μm] |

| 6 | 10 | 0 | 7 | 2 | 13 | 8 | 23 | 14 | 29 |

| 10 | 18 | 0 | 9 | 3 | 18 | 11 | 25 | 18 | 33 |

| 18 | 24 | 0 | 10 | 5 | 20 | 13 | 28 | 20 | 36 |

| 24 | 30 | 1 | 11 | 5 | 20 | 13 | 28 | 23 | 41 |

| 30 | 40 | 1 | 11 | 6 | 20 | 15 | 33 | 28 | 46 |

| 40 | 50 | 1 | 11 | 6 | 23 | 18 | 36 | 30 | 51 |

| 50 | 65 | 1 | 15 | 8 | 28 | 23 | 43 | 38 | 61 |

| 65 | 80 | 1 | 15 | 10 | 30 | 25 | 51 | 46 | 71 |

| 80 | 100 | 1 | 18 | 12 | 36 | 30 | |||

Cages

Cylindrical roller bearings are usually equipped with Metal cages equipped.

Materials

The deep groove ball bearings are made in your standard version from the material 1.3505 (100Cr6) and manufactured with a minimum hardness of 58 HRC. On request, corrosion protected versions are available.

Your contact person

-

Roller bearings sales

-

+49 (2053) 497 - 36

-

Roler bearings

-

+49 (2053) 497 - 0

-

Opening hoursMo-Do.: 08:00 - 16:00

Fr.: 08:00 - 14:45

-

Delivery timesMo-Do.: 06:00 - 13:30

Fr.: 06:00 - 11:00

oder nach Absprache