Challenge

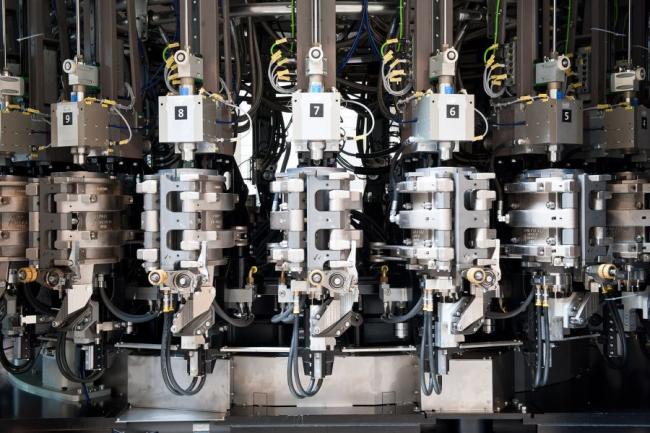

Due to increasing requirements (speed, load) on filling lines in the beverage industry, it was necessary for our customer to optimize the efficiency and performance of the track rollers used in its cam controls. At the same time, the tribological contact between the raceway and outer ring was to be optimized in such a way that this could take place over the service life with minimum wear without the use of lubricants.

Küpper solution

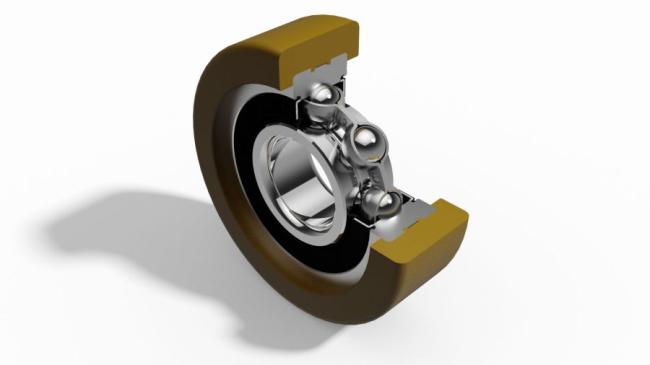

Combines a tribologically optimized high-performance plastic with a track roller that is matched in its constructive design to the application in the beverage industry.

Customer benefits

- Increased service life due to reduced wear behavior

- Lower maintenance requirements for cam control due to freedom from lubricants

- Improved hygienic conditions due to lubricant-free raceways

- optimized food-grade rolling bearing lubricant

- cost-optimized manufacturing process

- complete form fit of the plastic shell with the outer ring

Your contact person

-

Roller bearings sales

-

+49 (2053) 497 - 36

-

Roler bearings

-

+49 (2053) 497 - 0

-

Opening hoursMo-Do.: 08:00 - 16:00

Fr.: 08:00 - 14:45

-

Delivery timesMo-Do.: 06:00 - 13:30

Fr.: 06:00 - 11:00

oder nach Absprache