Customized Lubrication of Bearings and Rollers

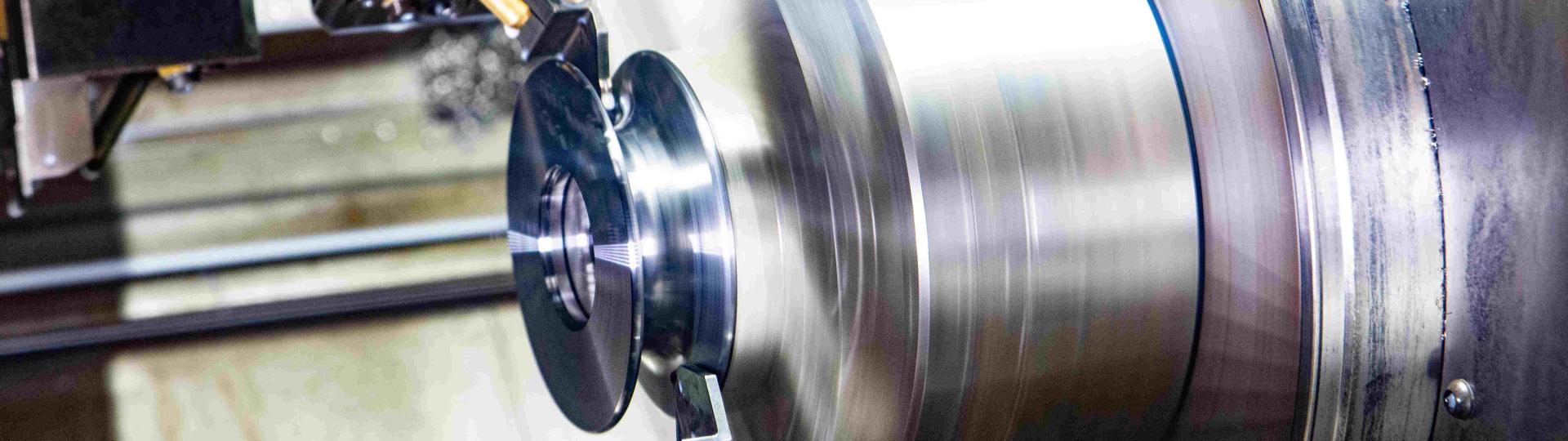

Professional lubrication of bearings and rollers is a critical step to ensure functionality and long service life. Our core expertise lies in the combination of automated cleaning, precise dosing technology, and application systems customized to each bearing type.

Prior to lubrication, we carry out fully automated cleaning of all bearing components to remove residues, particles, and oils. Our technical cleanliness requirements for rolling bearings are based on the DIN ISO 7544 standard. Especially when using high-temperature lubricants based on PTFE/PFPE, our PER cleaning system is essential – it ensures optimal adhesion conditions on metallic surfaces.

The lubrication process itself is carried out in our assembly department using volume-controlled precision dosing systems. To ensure even distribution of the lubricant within the raceways, specially developed grease heads are used. These are custom-made for each bearing type and roller type, taking into account geometry, grease type, volume, and sealing concept.

These tailor-made grease heads ensure that lubricant is precisely applied to the raceways without damaging seals or sensitive components. This is particularly important for high-temperature bearings, lifetime-lubricated applications, and special bearing designs.

This optimized lubrication leads to a better running-in phase, reduced friction, and improved long-term stability of the lubricant film – even under extreme operating conditions.

Our assembly lines are perfectly designed to meet these requirements and allow flexible setups for small batches, custom solutions, or prototype projects.

Your contact person

-

Roller bearings sales

-

+49 (2053) 497 - 36

-

Roler bearings

-

+49 (2053) 497 - 0

-

Opening hoursMo-Do.: 08:00 - 16:00

Fr.: 08:00 - 14:45

-

Delivery timesMo-Do.: 06:00 - 13:30

Fr.: 06:00 - 11:00

oder nach Absprache