Maintenance-Free Bearings and Track Rollers – Maximum Availability with Minimal Effort

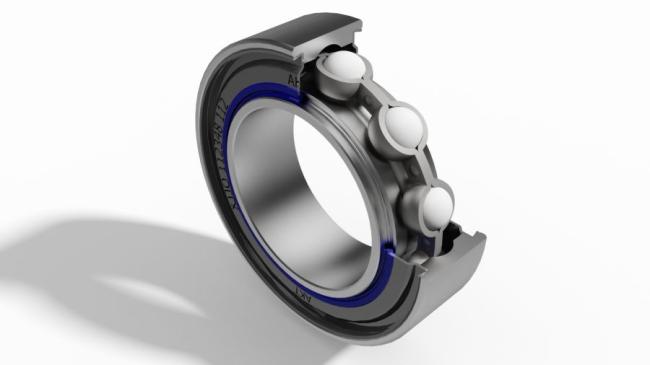

Maintenance-free bearings and track rollers are essential in today’s systems where maximum reliability, minimal downtime, and low maintenance costs are critical. Our specially developed bearing solutions allow for inspection-free continuous operation – even under extreme conditions.

Thanks to innovative design, advanced materials, and precise manufacturing, our maintenance-free bearings and hybrid bearings achieve significantly longer service life compared to conventional solutions made of bearing steel. This not only reduces maintenance costs but also increases the productivity of your systems in the long term.

Advantages of Maintenance-Free Bearings and Track Rollers

Our maintenance-free solutions are based on sophisticated engineering and specifically designed to eliminate the need for regular lubrication. Key features at a glance:

- Use of solid lubricants for long-lasting lubrication

- Wear-reducing surface coatings for extended service life

- Optimized cage design for low friction and quiet operation

- Frictionless steel seals in the standard version

- Optional: contact seals for operating temperatures up to 200 °C

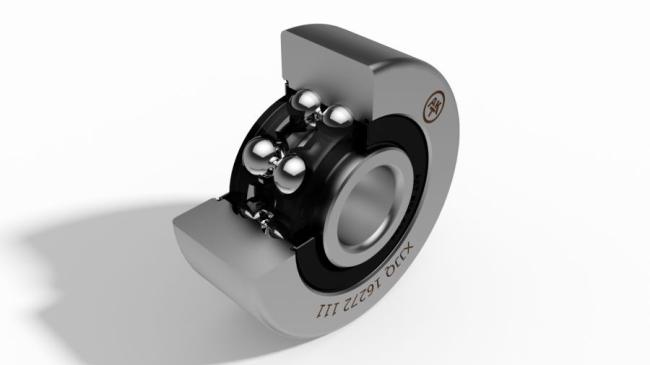

Hybrid Bearings with Ceramic Rolling Elements – Peak Performance for Demanding Applications

Hybrid bearings combine the advantages of conventional steel rings with the outstanding properties of ceramic rolling elements. This material combination opens up new application areas – especially where traditional bearings reach their limits:

- Rings made of high-grade bearing steel, combined with ceramic rolling elements made of silicon nitride (Si₃N₄)

- Electrical insulation properties – ideal for current passage or inductive environments

- Higher bearing stiffness compared to standard steel ball bearings

- Lower operating temperatures thanks to significantly reduced friction

- Self-lubricating properties of the ceramic balls – ideal for low-maintenance applications

- Extremely smooth running even at high speeds

- Proven in oscillating movements where a sufficient lubricant film cannot form

- Equipped with frictionless steel seals as standard, optionally with contact seals for temperatures up to 200 °C

Fields of Application

Our maintenance-free bearing solutions are successfully used in numerous industries:

- Conveyor systems

- Food processing

- Agricultural machinery

- Medical technology

- Packaging machines

For more information or a personal consultation about maintenance-free bearings or hybrid solutions, feel free to use our contact form.

Your contact person

-

Roller bearings sales

-

+49 (2053) 497 - 36

-

Roler bearings

-

+49 (2053) 497 - 0

-

Opening hoursMo-Do.: 08:00 - 16:00

Fr.: 08:00 - 14:45

-

Delivery timesMo-Do.: 06:00 - 13:30

Fr.: 06:00 - 11:00

oder nach Absprache