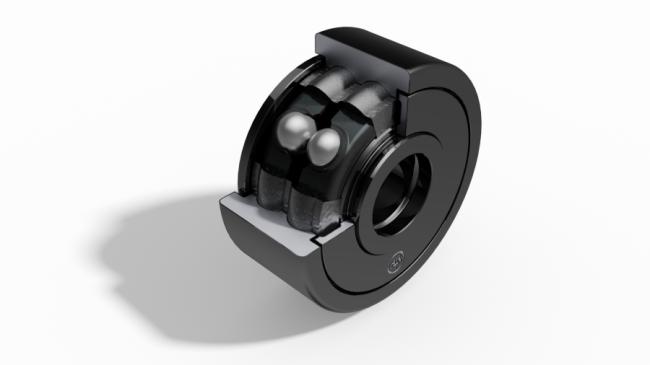

High temperatures occurring in customer applications place particularly high demands on the design of our rolling bearings and track rollers. Special design features must be taken into account and materials suitable for high temperatures must be selected for seals and cages. The selection of the lubricant suitable for the application depends here to a large extent on the temperature range and the product requirements. Basically, our rolling bearings and track rollers for high-temperature applications are divided into products which are lubricated with high-temperature greases or solid lubricant.

High temperature bearings/.track rollers - grease lubricated

- suitable for high temperature applications up to 250°C

- suitable for low speeds

- optional paint compatible design for painting systems in the automotive

- life lubricated design possible

- optional lubricant for food contact (NSF H1)

- on request equipment with relubrication systems

- basic design with frictionless steel sealing systems

- on request equipment with abrasive seals up to 200°C

High temperature bearings/track rollers -. solid lubricated

- suitable for high temperature applications up to 350°C

- suitable for low speeds

- lubricated for life

- lubricant based on graphite-.molybdenum disulfide-based

- run-in behavior optimized by surface coating

- basic design with frictionless steel sealing systems

- equipped with abrasive seals up to 200°C

For further information or inquiries about our rolling bearings and track rollers for high temperature applications, please do not hesitate to contact our service team via the contact form.

Your contact person

-

Roller bearings sales

-

+49 (2053) 497 - 36

-

Roler bearings

-

+49 (2053) 497 - 0

-

Opening hoursMo-Do.: 08:00 - 16:00

Fr.: 08:00 - 14:45

-

Delivery timesMo-Do.: 06:00 - 13:30

Fr.: 06:00 - 11:00

oder nach Absprache