Features needle roller and cage assemblies

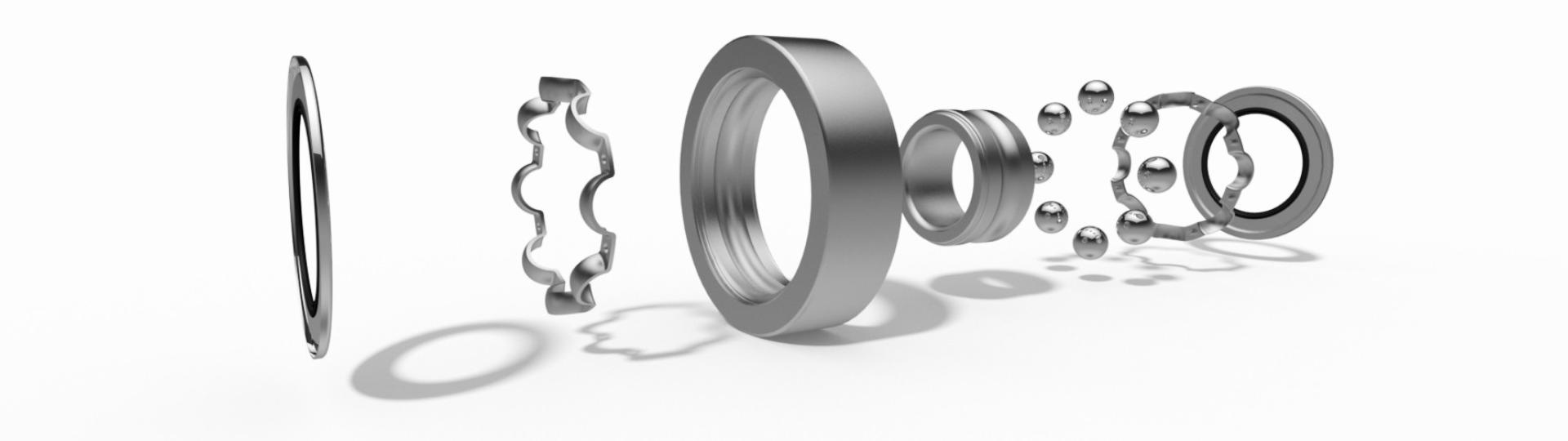

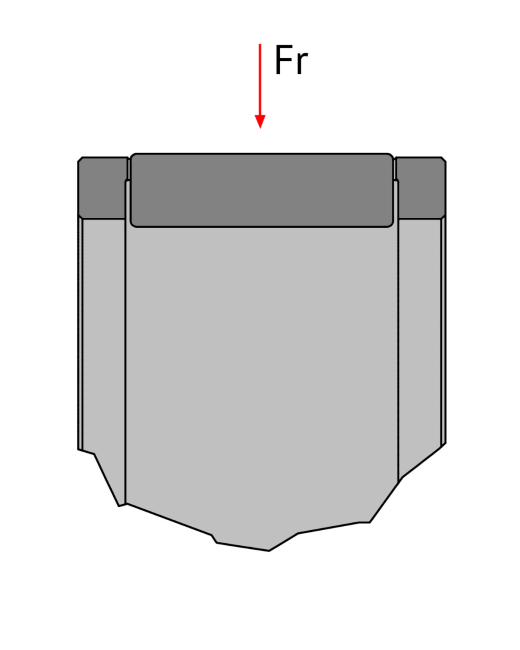

Needle roller and cage assemblies consist only of a needle cage and the associated needles. The design of needle roller and cage assemblies is usually single or double row. They absorb high radial forces and, due to the lack of bearing rings, run directly on the shaft and in the housing. The advantage of needle roller and cage assemblies is their low overall height, which corresponds to the diameter of the needle used. Thus, a bearing is possible on a small installation space.

Needle roller and cage assemblies must be secured axially by constructive securing elements (e.g. snap rings). The design of the needle roller and cage assemblies requires a hardened and ground raceway on the shaft and in the housing. For this purpose, a minimum surface hardness of the shaft of 670 HV with sufficient hardening depth (SHD/CHD) is recommended.

Loads

Our service team will be pleased to provide information on the values for the load capacity of the needle roller and cage assemblies.

Accuracies

The accuracy of the needle roller and cage assemblies is influenced by the adjacent construction of the raceway on the shaft and in the housing. The width tolerance can be taken from DIN 5405-1.

Bearing clearance

The bearing clearance of the drawn cup needle roller and cage assemblies results from the adjacent construction. For more information on the design of the adjacent construction, our service team will be happy to provide you with information.

Cages

Pin-sleeves can be supplied with Plastic or metal cages can be equipped.

Materials

The rolling elements of the drawn cup needle roller bearings are made in your standard version from the material 1.3505 (100Cr6) and manufactured with a minimum hardness of 58 HRC.

Your contact person

-

Roller bearings sales

-

+49 (2053) 497 - 36

-

Roler bearings

-

+49 (2053) 497 - 0

-

Opening hoursMo-Do.: 08:00 - 16:00

Fr.: 08:00 - 14:45

-

Delivery timesMo-Do.: 06:00 - 13:30

Fr.: 06:00 - 11:00

oder nach Absprache