The fundamental basis for the greasing of rolling bearings and track rollers is the cleaning and pre-treatment of the metallic surfaces before greasing. Our washing processes in automated washing systems remove even the smallest particles that could affect the service life of the rolling bearings.

In the field of pre-treatment of rolling bearings, which are greased with high-temperature greases, we have acquired extensive know-how. Through the special pre-treatment, in the automated PER cleaning system that we have acquired for this purpose, the metallic surfaces are completely cleaned of disturbing oil and grease residues. This is crucial for the adhesion and functionality of the PTFE-based high-temperature lubricants.

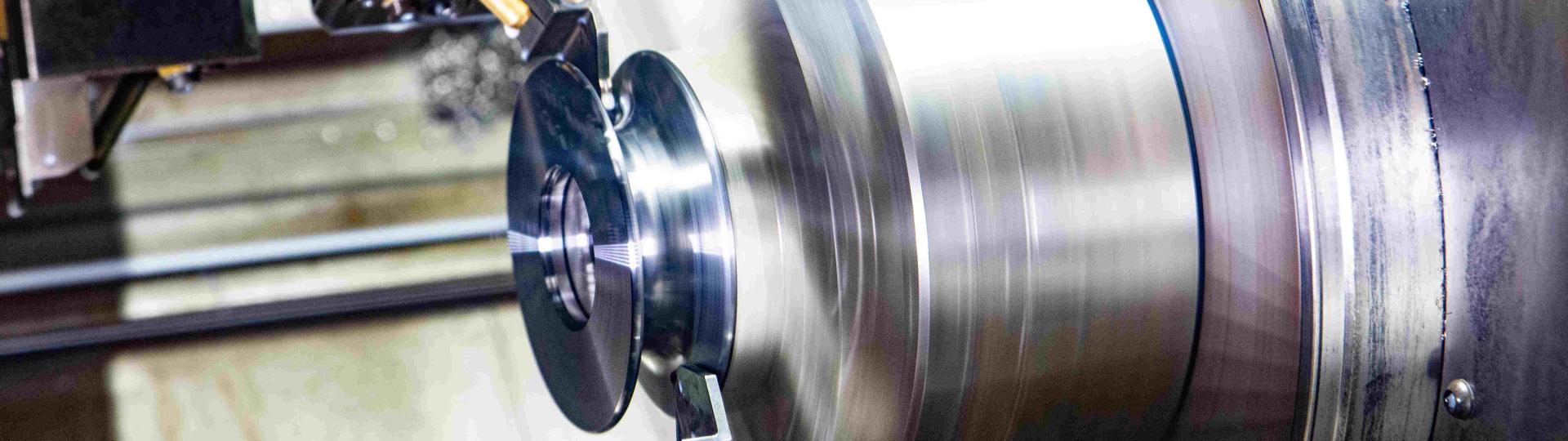

The greasing of our rolling bearings and track rollers is carried out with volume-controlled metering devices that ensure process-reliable greasing. The special design of the metering devices ensures that the lubricant is distributed evenly in the raceways of the rolling bearings, thus optimizing grease distribution when the bearing is run in.

Your contact person

-

Roller bearings sales

-

+49 (2053) 497 - 36

-

Roler bearings

-

+49 (2053) 497 - 0

-

Opening hoursMo-Do.: 08:00 - 16:00

Fr.: 08:00 - 14:45

-

Delivery timesMo-Do.: 06:00 - 13:30

Fr.: 06:00 - 11:00

oder nach Absprache