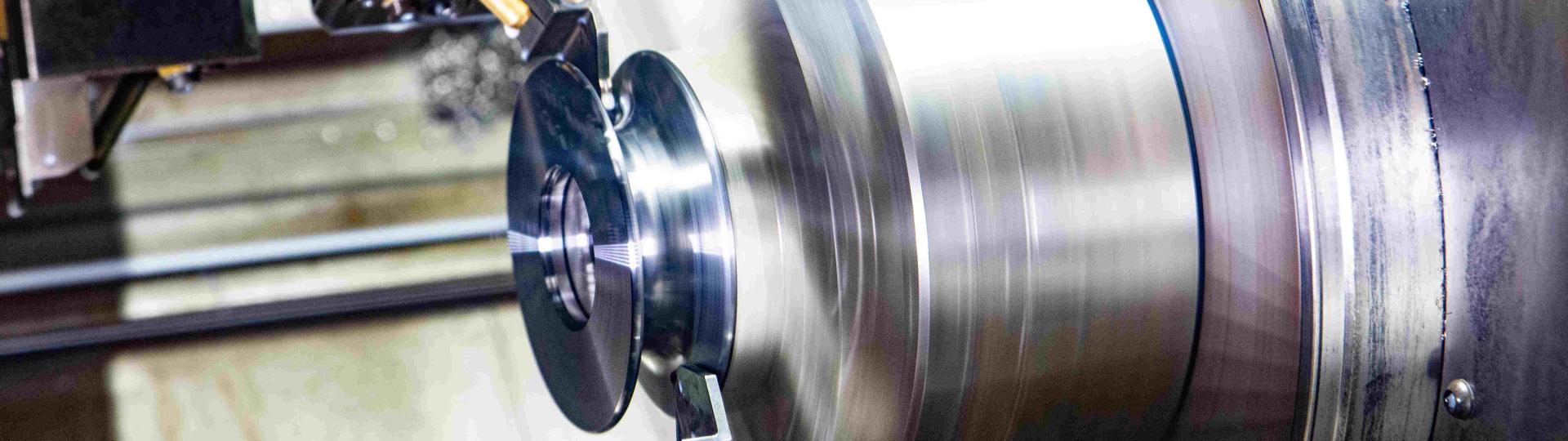

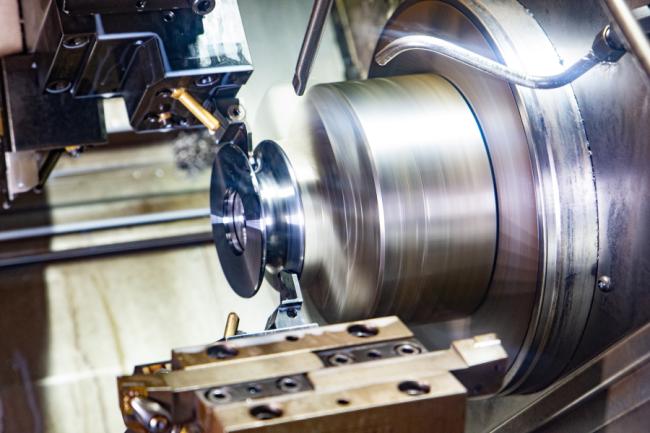

The path of each rolling bearing from our in-house production begins in our turning shop. Here, entirely according to customer requirements, the contours of our rolling bearing rings and components are pre-machined.

Our machinery includes several multi-spindle automatic lathes with cam control as well as with additional NC axes. Thus, we are also set up for complex workpiece geometries in medium and large series production.

For small and medium series production, several CNC lathes - also with driven tools - are available. Milled surfaces on bolts, transverse and lubrication holes can be realized so completely according to customer requirements. Complex milling contours and drilling patterns with the highest accuracy we produce on our 5-axis CNC milling center.

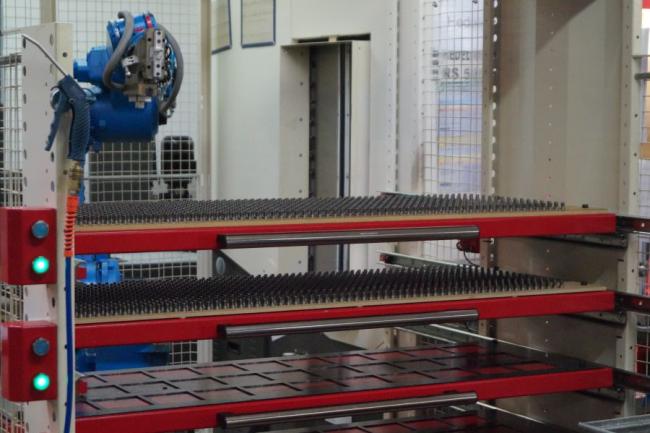

Currently made investments in a new, highly productive CNC machine with parallel processing on two spindles and linear handling portal, as well as in a highly flexible robot cell at our milling center, put us in a position to manufacture workpieces with the highest demands on accuracy and tolerance economically and process-safe.

Whether from bar, from saw cuttings, forging or pre-turned parts - we are equipped for your tasks, both in small and large quantities!

Your contact person

-

Roller bearings sales

-

+49 (2053) 497 - 36

-

Roler bearings

-

+49 (2053) 497 - 0

-

Opening hoursMo-Do.: 08:00 - 16:00

Fr.: 08:00 - 14:45

-

Delivery timesMo-Do.: 06:00 - 13:30

Fr.: 06:00 - 11:00

oder nach Absprache