Specially in the field of maintenance and spare parts procurement, there is often the problem of long delivery times and different dimensions for the various competitor products. This is where Artur Küpper GmbH & Co.KG comes in, because through our own production and design/development, we are able to respond to the demands of the user, to recognize and use any existing potential for improvement.

Our solutions have already been installed for a long time at well-known plant manufacturers and users and show that improvements in service life and simplifications in maintenance have been achieved through the individual adaptations. The delivery times and the possibility to realize the dimensions individually to the installation space according to the customer's specifications are a big plus of our products. Modern machinery, accompanying production documentation and the corresponding quality inspection and assurance ensure a transparent and traceable insight into our claim to a successful product.

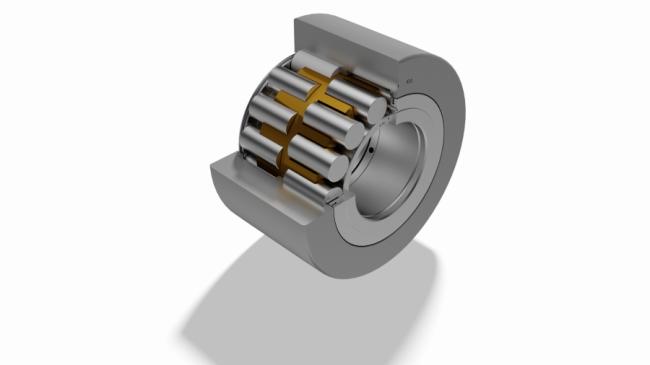

Support rollers for rolling mills

- suitable for very high loads

- individual adaptation to existing lubrication systems

- limited tolerances (P6)

- sorted by height groups on request

- high running accuracies

- suitable for high strip speeds

- optimized sealing systems

- up to outer diameter 350 mm

- Examples of applications:

- sheet mill

- strip mill

- dressing mill / re-rolling mill

- cold mill

- hot mill

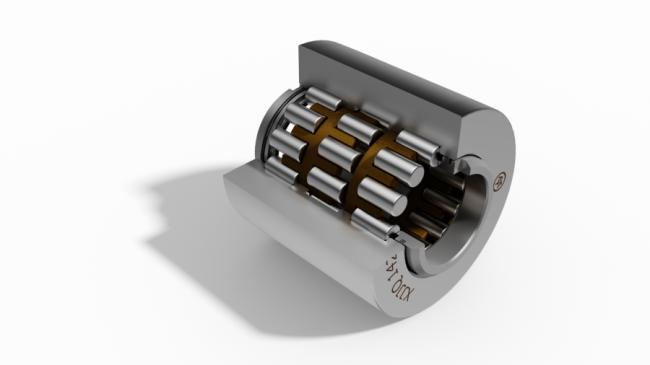

Rollers/support rollers for the metal industry

- suitable for high loads

- optimized for harsh environmental conditions

- suitable for a wide speed range

- greased with premium antifriction bearing greases

- high running accuracies

- optionally extended sealing against external environmental influences (e.g.B. Scale)

- optional low-friction running

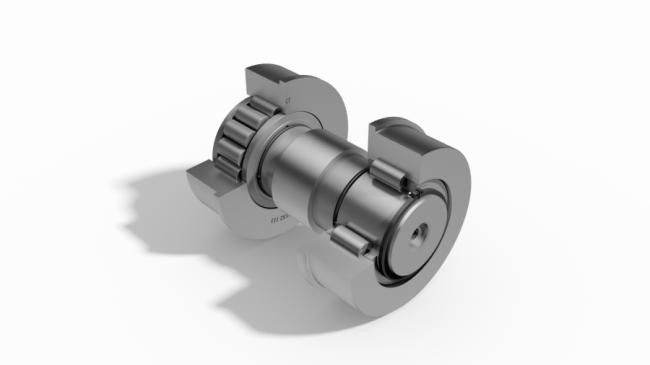

Track rollers/support rollers for straightening / and measuring processes

- special coating for straightening- / and measuring products

- reduced starting torque

- low friction running

- high running accuracies

- suitable for a wide speed range

- optional extended sealing against external environmental influences (e. g.B. Rolling oil)

More information about RLBS support rollers

Support rollers can be used due to the special hardening of the outer rings by regrinding the outer diameter can be reconditioned by us. This is particularly necessary when processing high quality metal strips.

For further information or inquiries about our rolling bearings and track rollers for high temperature applications, please contact our service team via contact form at any time.

Your contact person

-

Roller bearings sales

-

+49 (2053) 497 - 36

-

Roler bearings

-

+49 (2053) 497 - 0

-

Opening hoursMo-Do.: 08:00 - 16:00

Fr.: 08:00 - 14:45

-

Delivery timesMo-Do.: 06:00 - 13:30

Fr.: 06:00 - 11:00

oder nach Absprache