Customers expect a high level of quality from a specialized medium-sized company that manufactures in Germany out of conviction. We have been meeting this expectation for decades - and can document it in black and white:

Our quality management system has been certified to DIN EN ISO 9001 since 1997. And our factory standards go far beyond the existing DIN standards. Individual arrangements and coordination regarding further test parameters are agreed with our customers as required.

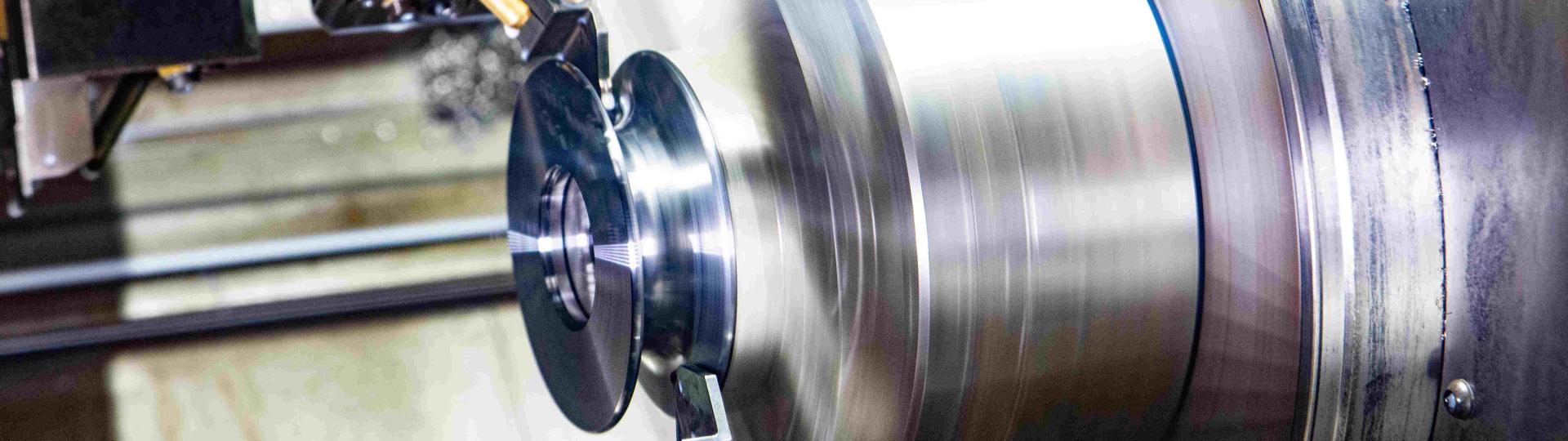

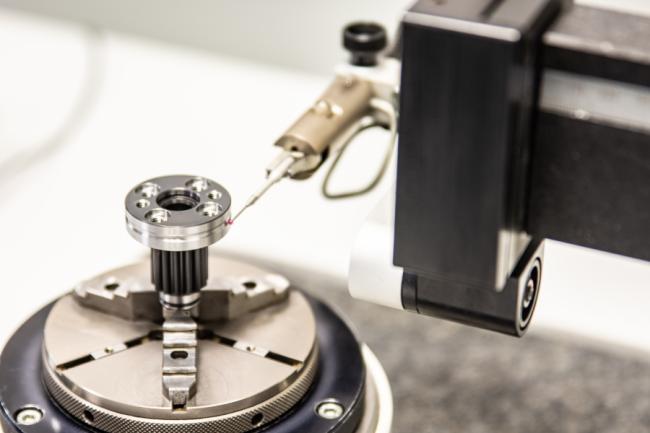

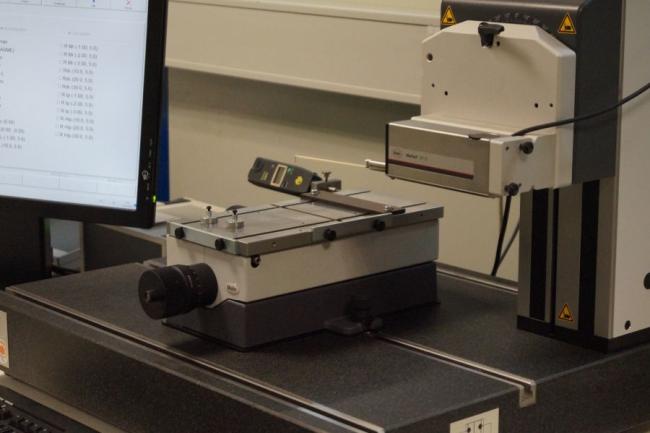

These are important prerequisites for the durability and excellent running properties that are characteristic of our product. Each work step is monitored and documented during production using modern testing equipment. Process-integrated measuring techniques guarantee the best running properties and excellent concentricity values. With our testing equipment, e.g. combined contour graphs with surface measuring equipment, we ensure the consistently high quality of our products.

The high-quality materials and state-of-the-art manufacturing technologies also help to ensure that our rolling bearings meet the highest quality standards. Initial sample test reports and other quality assurance documents are delivered with our rolling bearings as agreed. Upon request, we will also provide the IMDS No. (commonly used in the automotive industry) of our rolling bearings.

Your contact person

-

Roller bearings sales

-

+49 (2053) 497 - 36

-

Roler bearings

-

+49 (2053) 497 - 0

-

Opening hoursMo-Do.: 08:00 - 16:00

Fr.: 08:00 - 14:45

-

Delivery timesMo-Do.: 06:00 - 13:30

Fr.: 06:00 - 11:00

oder nach Absprache