An important factor in achieving the longest possible service life for the rolling bearings and track rollers we manufacture is the use of state-of-the-art hardening processes to ensure an optimum hardness structure. For this purpose, we cooperate with long-term, regularly audited partners.

In most applications of our rolling bearings, the classic rolling bearing steel 1.3505 (100Cr6) is used. This rolling bearing steel is a classic through-hardener, in which a continuous martensitic structure forms during the hardening process.

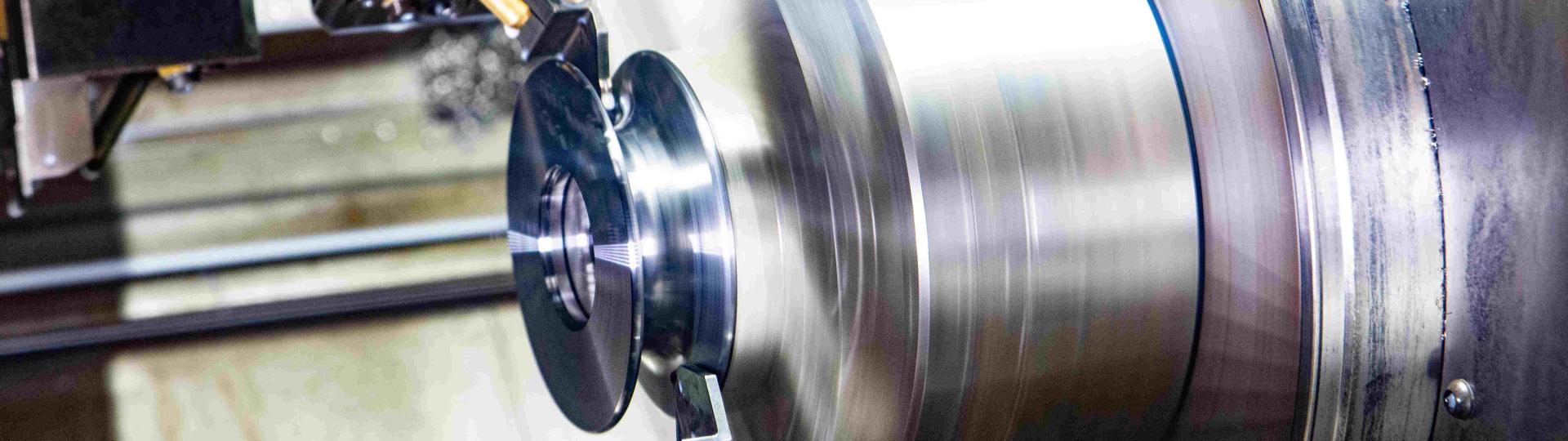

In classic hardening, the material to be treated is heated in the hardening furnace to a temperature at which an austenitic structure forms. Rapid cooling of the material (e.g. in OIL) transforms austenite into martensite. Due to the structure of the martensitic microstructure that forms, our rolling bearings and track rollers achieve the hardness required for the application.

For special applications of our rolling bearings and track rollers, for example in areas of high dynamic loads, a tough microstructure is desired. In order to achieve sufficient rolling strength in the areas of the raceways of the rolling elements, only partial areas of the rolling bearing rings are hardened. For this purpose, we use surface hardening processes such as induction hardening, case hardening or nitriding.

Your contact person

-

Roller bearings sales

-

+49 (2053) 497 - 36

-

Roler bearings

-

+49 (2053) 497 - 0

-

Opening hoursMo-Do.: 08:00 - 16:00

Fr.: 08:00 - 14:45

-

Delivery timesMo-Do.: 06:00 - 13:30

Fr.: 06:00 - 11:00

oder nach Absprache