Quality "Made in Germany" - according to this maxim, we have always further adapted our grinding machine concept to the increasing customer requirements! Whether surface, - external or internal cylindrical grinding - we ensure that our bearing rings and components meet the highest quality requirements in dimension, shape and position!

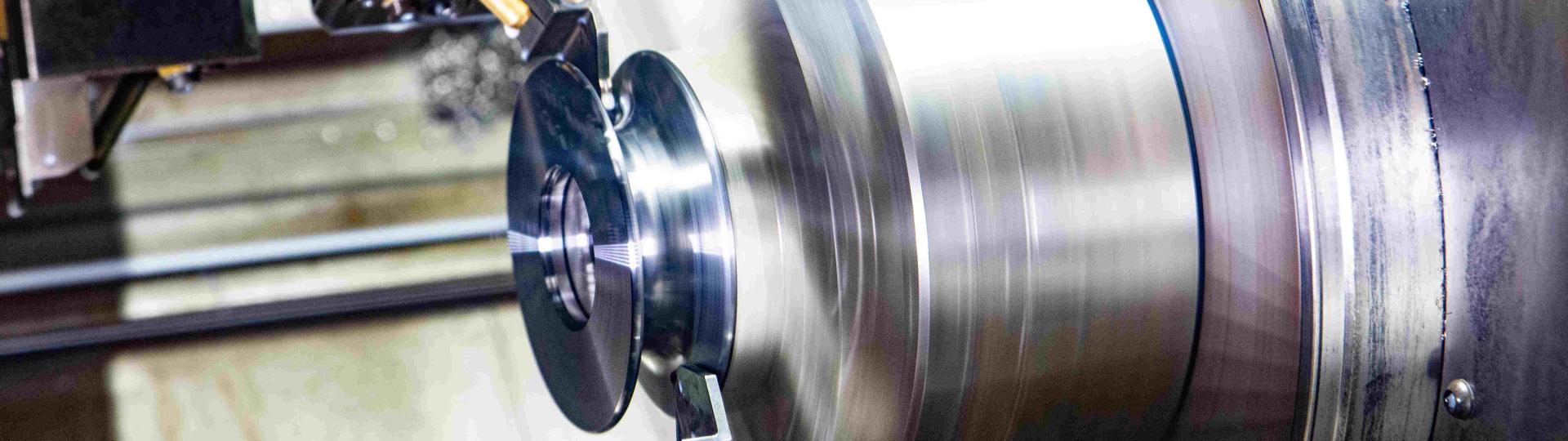

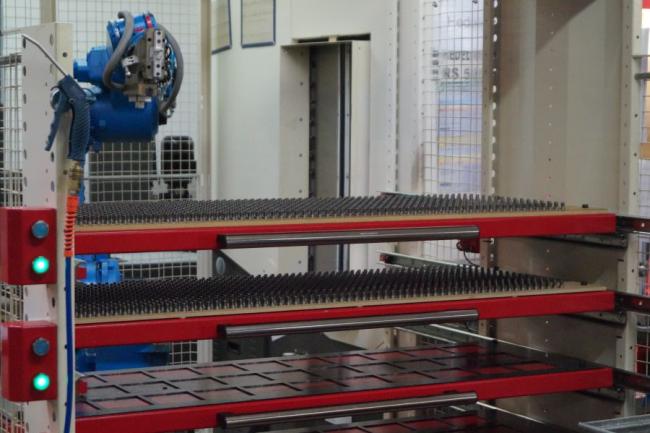

With machines for double side surface grinding and centerless external cylindrical grinding, we lay the foundation for further grinding processing in the narrowest micrometer range. We grind our raceways and sealing surfaces, depending on the workpiece and geometry, on high-precision CNC-controlled machines, some with up to 8 axes for combined external and internal machining in one clamping!

In addition to mechanical processing, the focus is always on quality assurance and the lubricant and filtration concept of the grinding systems. A new central coolant system and the latest devices for contour and surface measurement ensure that the quality of our products also meets the highest requirements in the future!

In addition to conventional grinding processing, investments in the latest hard turning technology allow us the high-precision machining of even the most complex contours with standard turning tools in one clamping!

Your contact person

-

Roller bearings sales

-

+49 (2053) 497 - 36

-

Roler bearings

-

+49 (2053) 497 - 0

-

Opening hoursMo-Do.: 08:00 - 16:00

Fr.: 08:00 - 14:45

-

Delivery timesMo-Do.: 06:00 - 13:30

Fr.: 06:00 - 11:00

oder nach Absprache