Profile shapes for outer rings

For many installation situations, the critical factor is not the load rating of the bearing arrangement within a track or yoke type track roller, but the insufficient wear resistance in the contact between the outside surface (outer ring) and the rolling partner (rail). The outer rings, which are usually thick-walled, can, if the profile shape is incorrectly selected, lead to premature wear on the rolling partner and thus to failure of the entire units.

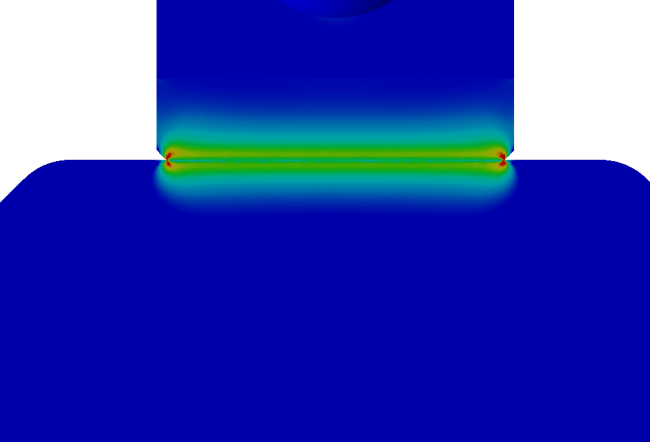

Rollers are frequently designed with crowned or straight profiles of the outer ring running surface. Cylindrical rollers with a straight profile can transmit high loads, but do not have a high tilt angle tolerance and therefore place very high demands on the accuracy of the connection geometries (Fig. 1).

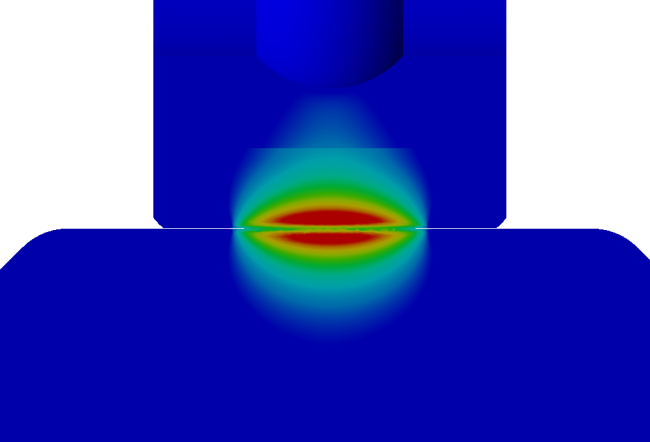

Rollers with a crowned profile are therefore often used to circumvent the problem of the low tilt angle tolerance, since this profile shape also tolerates higher skew positions. However, this leads to a significant increase in contact pressure (Fig. 2).

The combination of the two basic shapes, such as cylindrical-ball profiles, counteract these effects, but can only be used with sufficiently wide track or support rollers (e.g..B.: support rollers for multi-roll mills) can be used.

The Artur Küpper company has therefore developed and successfully tested an optimized profile shape for the running and support rollers. By using outer rings with optimized profiled shell surfaces, we are able to adapt the contact situation to your needs:

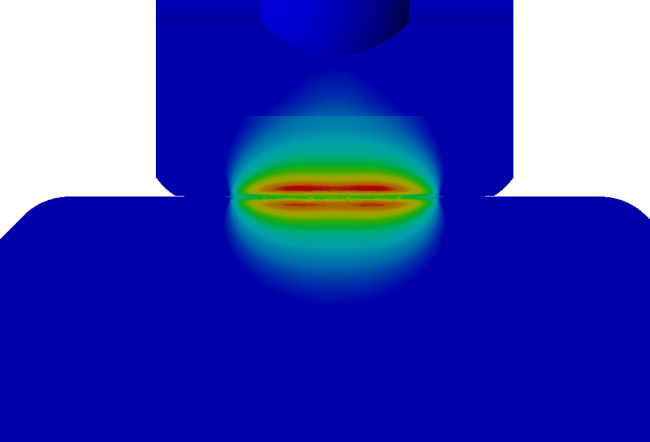

With the Wearprevent K-Opt® profile shape, an alternative to the crowned profile was found. The contact pressure has been significantly reduced, while tilt angles within the permissible skew of the inner bearing continue to be transmitted reliably.

The Wearprevent L-Opt® profile shape approaches the ideal of line contact for transmitting high loads without the risk of high stresses caused by edge runners, which can occur with the smallest skew of the outer ring.

With our developed design tools, we can create a specific profile shape for your specific task. In the design, we take into account possible misalignments from adjacent designs, the material of the rail or mating roller, and the environmental conditions.

In summary, adjusting the profile of the outer ring running surface:

- results in lower contact stresses

- lower wear on both rolling partners

- lower heat generation

- longer service life

And thus increased system availability, while reducing maintenance costs.

Your contact person

-

Roller bearings sales

-

+49 (2053) 497 - 36

-

Roler bearings

-

+49 (2053) 497 - 0

-

Opening hoursMo-Do.: 08:00 - 16:00

Fr.: 08:00 - 14:45

-

Delivery timesMo-Do.: 06:00 - 13:30

Fr.: 06:00 - 11:00

oder nach Absprache