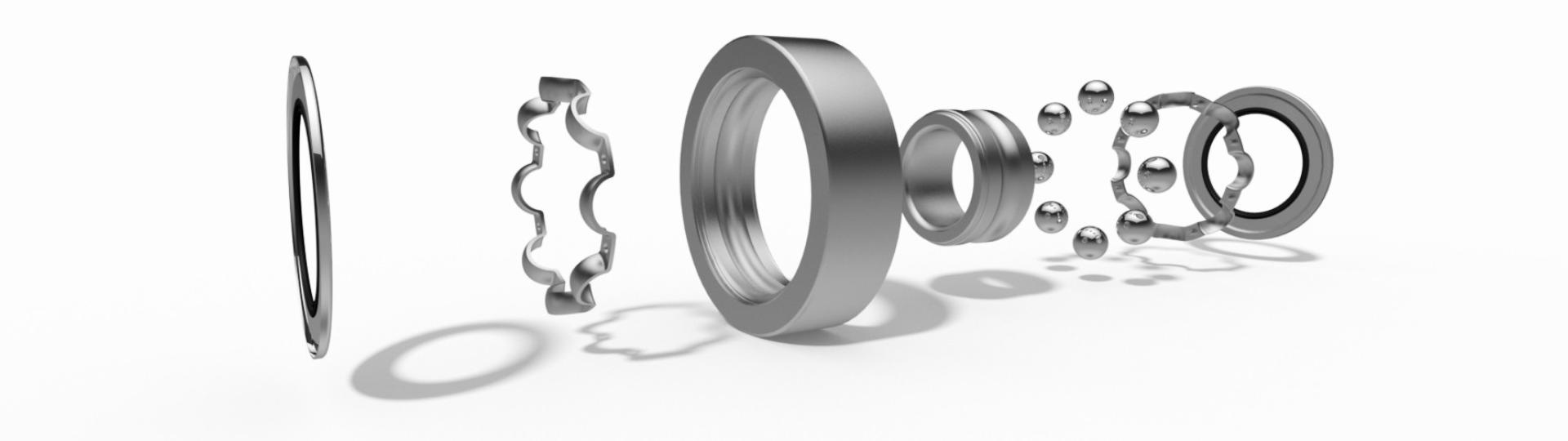

Bearing cages are used to keep the rolling elements at an equal distance apart. This keeps friction and heat generation to a minimum, distributes the load evenly and prevents the rolling elements from falling out.

Full complement or full complement rolling bearings do not require a cage. This means that more rolling elements can be used per rolling bearing, which significantly increases the load capacity. However, they are not suitable for speeds greater than approximately 300 rpm.

Depending on the requirements that the particular rolling bearing design must meet, cages made of different materials (steel, polyamide, peek, brass) are used in various designs. The design and material composition of the rolling bearing cage depends on various factors. Operating temperatures, speeds, special requirements (e.g. bearing misalignment) or the installation space in the rolling bearing are decisive factors in the final design of the rolling bearing cage.

Your contact person

-

Roller bearings sales

-

+49 (2053) 497 - 36

-

Roler bearings

-

+49 (2053) 497 - 0

-

Opening hoursMo-Do.: 08:00 - 16:00

Fr.: 08:00 - 14:45

-

Delivery timesMo-Do.: 06:00 - 13:30

Fr.: 06:00 - 11:00

oder nach Absprache