Precision Bottom Brackets for Demanding Bikes

Durable. Low-Maintenance. Pressure-Wash Resistant.

At Artur Küpper GmbH & Co. KG, we develop high-performance bottom brackets tailored to the needs of OEM bicycle manufacturers. Designed for extreme loads, long-term reliability and easy cleaning – ideal for e-bikes, touring and performance bicycles.

The Challenge: Pressure Washing, Dirt, Corrosion – Maximum Demands on the Bottom Bracket

In daily use, bicycles must withstand a wide variety of conditions. Mud, dust, sand and pressure washers put conventional bottom brackets under stress. Standard seals often fail – allowing water and dirt to penetrate, causing premature wear.

OEM manufacturers therefore require bottom bracket solutions that perform reliably in real-world conditions – retaining full sealing performance even after years of use and repeated high-pressure cleaning.

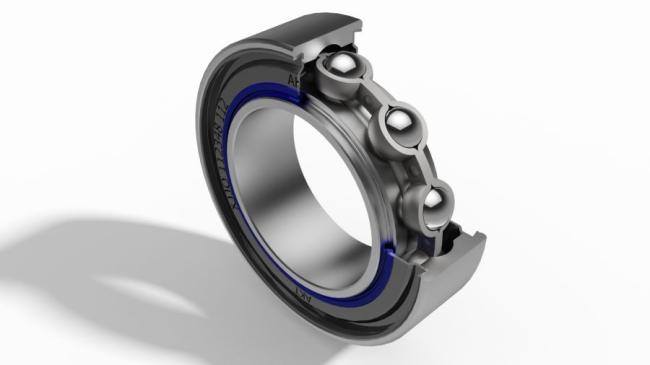

The Solution: Küpper Special Bottom Brackets with Innovative Sealing System

Our bottom brackets have been specially developed to meet the requirements of modern bicycle manufacturers. They combine industrial-grade technology with application-oriented design – ideal for e-bikes, touring bikes, trekking bikes and sporty urban bikes.

Technical Advantages:

- Form-fit sealing system with steel carrier

The integrated sealing lip is securely fixed in the housing – no washout under pressure. Superior to standard NBR seals. - Labyrinth seal against dirt and water

Multi-stage barrier effectively prevents contamination ingress. - Corrosion-resistant materials

All components are designed for maximum durability and environmental resistance. - Compact design for limited installation space

Perfect integration into bottom bracket shells – even in tight spaces. - Low-friction operation despite sealing

Minimal friction ensures a smooth and efficient riding experience.

Optional: High-End Hybrid Bearings with Ceramic Balls and Stainless Steel Races

For particularly high-performance bicycle models, we also offer our bottom bracket solution as a hybrid bearing:

- Ceramic balls (Silicon Nitride, Grade 10):

Especially lightweight, smooth and wear-resistant – for minimal friction and long service life. - Stainless steel races:

Corrosion-resistant and durable even under aggressive cleaning agents and environmental influences. - Noticeable performance advantages:

Less friction, higher efficiency, longer durability – ideal for e-bikes, cargo bikes and high-performance bikes.

Your Benefits as a Manufacturer:

- ✔Pressure-wash resistant bottom brackets – sealed against water and dirt up to 130 bar

- ✔Low-maintenance & durable – fewer service requirements

- ✔Corrosion protection through stainless steel and sealing technology

- ✔Made in Germany – developed and produced in Velbert

- ✔Reliable series production for OEM customers

Over 10 Years of Experience in Bottom Brackets – Over 90 Years of Expertise in Bearings

For over 90 years, Artur Küpper has stood for quality and precision in bearing technology – made in Germany. Our more than 10 years of experience in bicycle bottom brackets directly informs the development of robust, low-maintenance and high-performance solutions for the bicycle industry.

Thanks to our industrial background, we combine the highest manufacturing standards with the specific requirements of modern bicycle manufacturers – for long-lasting bottom bracket units that remain reliable even under extreme conditions.

👉 Contact us for samples or technical consultation.

Your contact person

-

Roller bearings sales

-

+49 (2053) 497 - 36

-

Roler bearings

-

+49 (2053) 497 - 0

-

Opening hoursMo-Do.: 08:00 - 16:00

Fr.: 08:00 - 14:45

-

Delivery timesMo-Do.: 06:00 - 13:30

Fr.: 06:00 - 11:00

oder nach Absprache