Lubricants - Effective rolling bearing lubrication

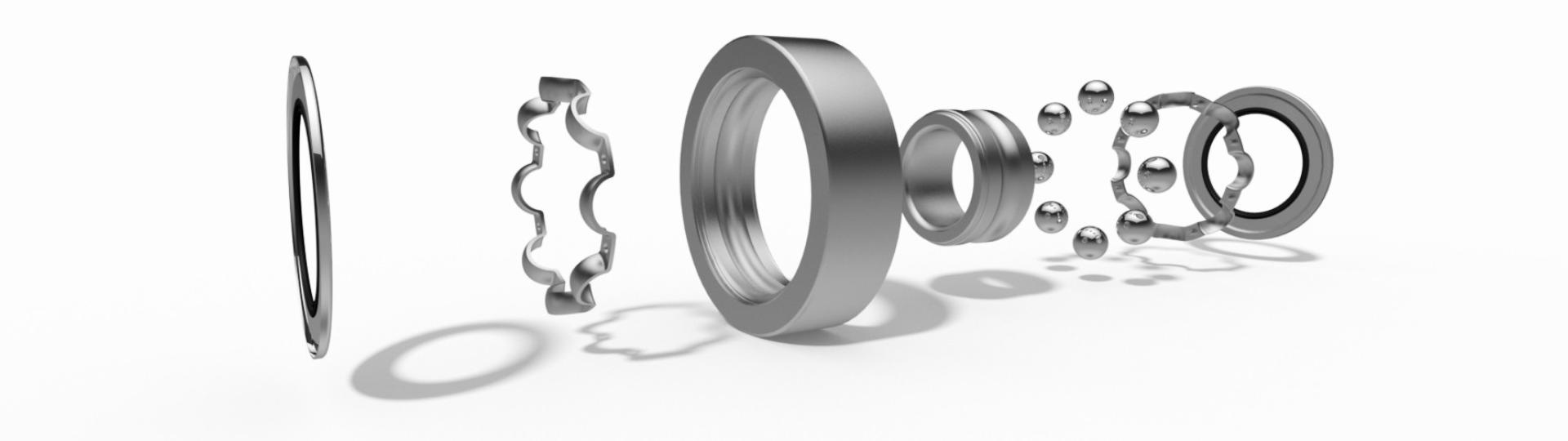

The service life of rolling bearings is largely dependent on the choice of the optimum lubricant. For years, we have been working closely with experts from practice and universities in the field of tribology.

As a system supplier, we are committed to responsibly and responsibly assembling the right components in our rolling bearings so that the maximum service life can be achieved. In order to confirm the empirical values available to us, we carry out comparative tests with various lubricants from different manufacturers directly in the plants of long-standing customers on a rotational basis.

| Application | Temperature | Composition | EP additive | ||

| [°C] | Base oil | Soap | |||

| KÜPPER-NT150-EP | Point contact | -30 to 150 | Mineral oil | Lithium | x |

| KÜPPER-NT150 | line contact | -40 to 150 | synthetic hydrocarbon | lithium | x |

| KÜPPER-NT140-LM | food | -40 to 140 | ester oil | silicate | |

| KÜPPER-HT250-LM | high temperature food | -40 to 250 | PFPE-Oil | PTFE | |

| KÜPPER-HT250-LA | High temperature | -20 to 200 | Ester oil | Polyurea | |

The thus obtained, practice-relevant results we implement immediately in our development projects.

The greasing of our rolling bearings is carried out on modern, finely meterable greasing equipment.

For rolling bearings that are filled with the particularly sensitive high-temperature lubricants, we have also developed a special pretreatment process.

This ensures that the high-temperature grease forms an optimum bond on the metallic surface in the rolling bearings. Even at borderline temperature ranges, the greases do not flow out in our high-temperature rolling bearings!

Your contact person

-

Roller bearings sales

-

+49 (2053) 497 - 36

-

Roler bearings

-

+49 (2053) 497 - 0

-

Opening hoursMo-Do.: 08:00 - 16:00

Fr.: 08:00 - 14:45

-

Delivery timesMo-Do.: 06:00 - 13:30

Fr.: 06:00 - 11:00

oder nach Absprache