The idlers, rolling bearings and track rollers for conveyor technology are subject to very special requirements - extremely heavy loads, a high throughput speed, vibrations and shock loads, high temperatures, or other adverse external influences present special challenges.

We are happy to develop together with you the optimal solution, which is best adapted to the given requirements and increases the reliability and availability of your conveyor systems. Of course, we can, thanks to our flexible manufacturing and assembly also design and manufacture entire assemblies.

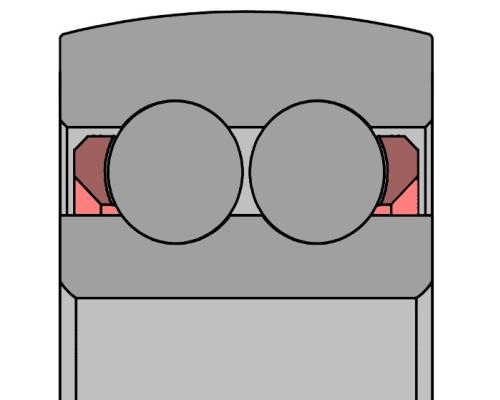

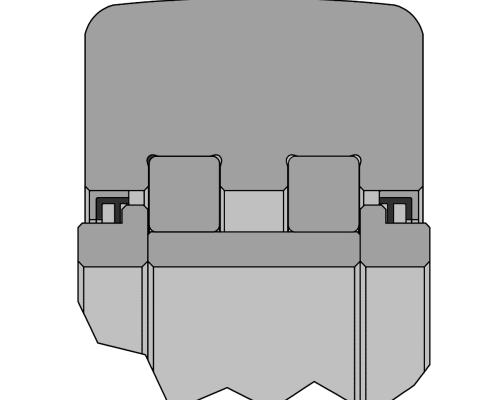

Track rollers correspond in their internal design to single or double row ball bearings and have a thick-walled, usually crowned outer ring. Optionally, they can be equipped with a combined inner ring

Yoke type track rollers are single or double row roller bearings consisting of a thick-walled, usually crowned outer ring and cylindrical rolling elements (needles or cylindrical rollers). The outer

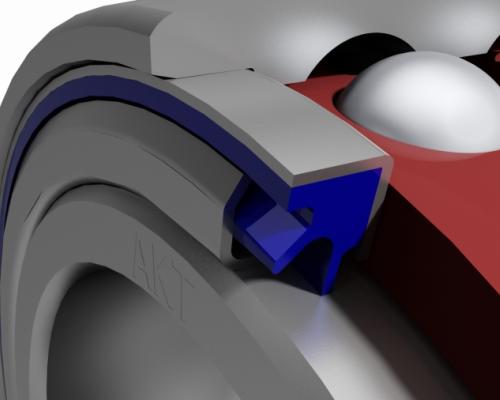

Boost uptime with maintenance-free bearings and hybrid bearings from AKT. Featuring ceramic balls, solid lubrication, and frictionless seals—ideal for high-speed, low-maintenance, and demanding

Protect your bearings and rollers with Corrprevent® surface coatings – ideal for corrosion and wear protection in food, agriculture, and high-load industries. Durable, efficient, and proven. Get

Our rolling bearings can be equipped with a wide variety of sealing systems, depending on the application. Seals are necessary to protect the rolling bearings when they are exposed to dust, dirt