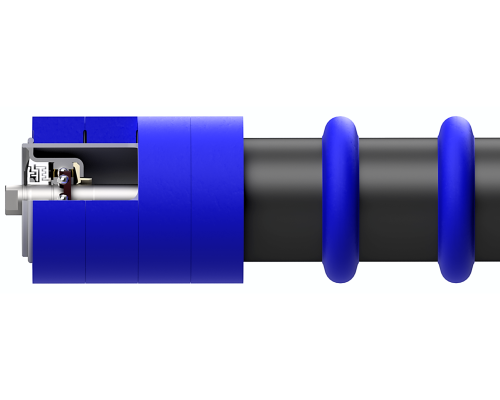

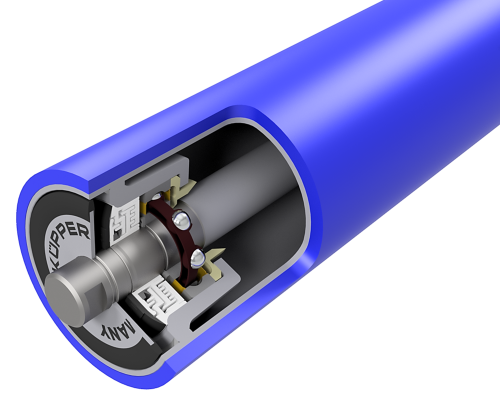

The development and manufacturing of conveyor rollers and idlers requires a great deal of engineering skills and creative solutions in order to meet high quality requirements and optimum structural design. Even if the conveyor rollers have in principle a simple design and basically consist of only a few essential components: shaft, roller tube, bearings and bearing seals. This is because the design of the conveyor rollers must be adapted to the specific requirements of the respective application, for example in regard of load capacity, running properties, wear resistance, corrosion resistance and noise emissions. New technology developments are often used in our company to improve the design of the conveyor rollers and to adapt them to the operating conditions (see e.g. "PU support rings").

The same applies to the idler frames, the "support frames" for the conveyor rollers - the quality of their design and manufacture has a major influence on their later operation - even though the designs are in principle quite simple in most cases.

We have selected a few examples of technology developments from our company that help us to extend the service life of conveyor rollers and increase the productivity of our customers:

Your contact person

-

Idlers sales

-

+49 (2041) 177 - 227

-

Idlers and conveyor belt rollers

-

+49 (2041) 177 - 0