Total cost of ownership

If you buy cheap, you buy twice. Sometimes even more often. We are happy to support you to prevent this from happening to you and help you to reduce your total cost of ownership respectively to keep it low in the long term. Our team always strives to offer you technically high-quality products at the best possible conditions.

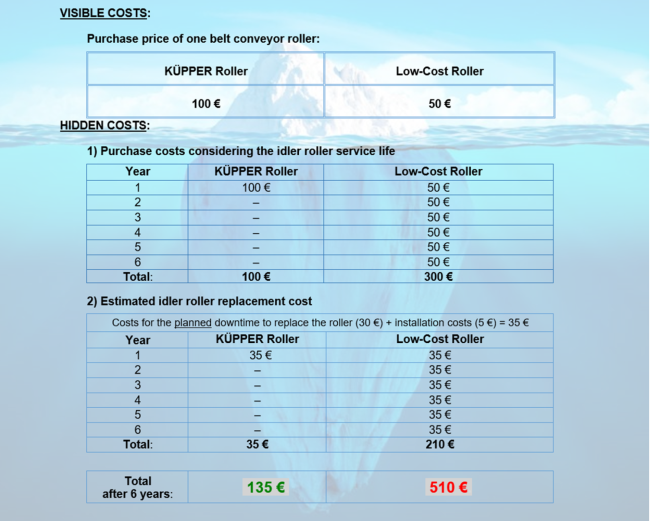

To make the best possible purchasing decision, we recommend that you not only focus on the price when purchasing conveyor rollers, but also always consider the total cost of ownership (TCO). In this way, you can also consider the hidden costs before making a purchase decision and thus calculate much more realistically and accurately.

Therefore, when comparing conveyor rollers, always consider cost items such as:

- Maintenance costs (e.g. costs for replacing idler rollers)

- Purchase costs for spare part conveyor rollers due to shorter service life

- Costs due to downtime

- Energy costs due to rolling resistance of the conveyor rollers

- Transport and storage costs for spare part conveyor rollers / replacement rollers

- Costs due to damages caused by defect idler rollers

These costs are often referred to as hidden costs, as they have to be calculated separately for each specific case. However, they sometimes form the significantly larger part of the expenditure compared to the pure purchase price, which in such cases only represents the tip of the iceberg.

Using a simple practical example of such a cost calculation (see below), we will show you that it is well worth investing in high-quality products.

Example of calculating the operating costs of an idler roller:

The following costs have not yet been considered in this example and would further increase the final difference significantly:

- Downtime costs due to unplanned downtimes. These costs can be extremely high, especially for critical conveyors such as conveyors of ship loaders.

- Costs due to damages to the belt caused by defect rollers (in the example the probability of experiencing this is at least 6 times higher with low-cost rollers!). Although the probability of the conveyor belt being damaged by an idler roller during operation is relatively low, the belt damage usually has serious consequences and causes very high costs.

- Transportation and storage costs for new idler rollers (delivery, testing, storage).

- Costs due to increased risks resulting from defect rollers (belt misalignment, fire incidents, e.g. with hot-running idler rollers).

By the way, our idler rollers have emergency running properties, which significantly reduces the risk of hot running.

The information on the service life of the belt conveyor rollers used in the example is by no means exaggerated but is based on our practical experience. Our idler rollers often have an average service life of over 10 years in bulk material conveyors used in mining industry.

Conclusion: The seemingly half-price "Low-Cost Roller" turns out to be almost four times as expensive during operation on closer inspection!

Finally, you will benefit several times over if you don't just base your purchase decision for idler rollers on the purchase price, but also consider the total costs of operation. We would be happy to support you in this and help you to increase the productivity and safety of your conveyors.

We look forward to your inquiry!

Your contact person

-

Idlers sales

-

+49 (2041) 177 - 227

-

Idlers and conveyor belt rollers

-

+49 (2041) 177 - 0