Anti-runback rollers and their application

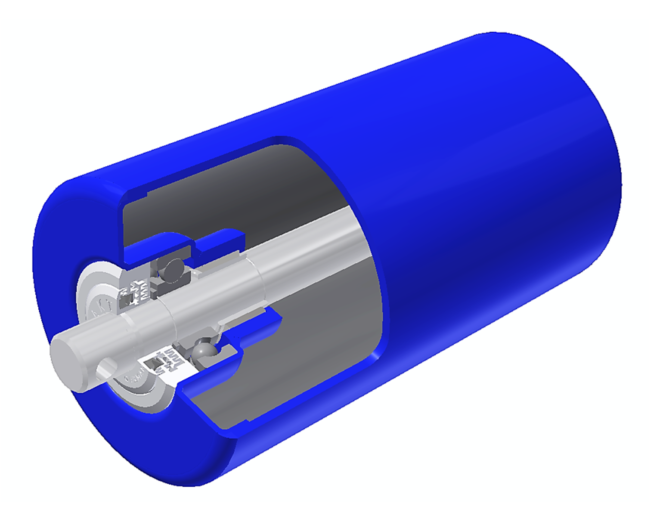

Anti-runback rollers are conveyor rollers with an integrated freewheel that only allows the roller tube to rotate in a specific direction.

Such conveyor rollers are mostly used in inclined belt conveyors. They are used to increase the safety of operation of the belt conveyor and prevent uncontrolled backward movement of the belt under the influence of gravity, which can happen, for example, if the event of belt snap or the conveyor brakes fail.

During maintenance work involving the opening of the belt, e.g. when changing the belt or repairing the belt by replacing a damaged belt section, the anti-runback rollers also prove to be very practical, as they hold at least one side of the belt in position.

The integrated freewheel stops the roller tube immediately if it tries to rotate backwards. This is why the term "brake roller" would be not so precise applied to this type of rollers, as the term "brake roller" is mostly used to subscribe of an other type of conveyor rollers - special rollers to control respectively to limit the conveying speed in conveyors for unit material handling.

Dimensions of the anti-runback rollers

Externally, the anti-runback rollers are very similar to the standard conveyor idler rollers. They can only be recognized by the markings indicating the intended direction of rotation. The anti-runback rollers can be used instead of standard conveyor rollers in the existing idler frames without any adjustments. The use of such rollers in garland idlers is also possible.

Your contact person

-

Idlers sales

-

+49 (2041) 177 - 227

-

Idlers and conveyor belt rollers

-

+49 (2041) 177 - 0