Composite rollers

Conveyor rollers with a roller tube made of composite materials (usually a combination of different plastics) are called composite rollers or composite idler rolls.

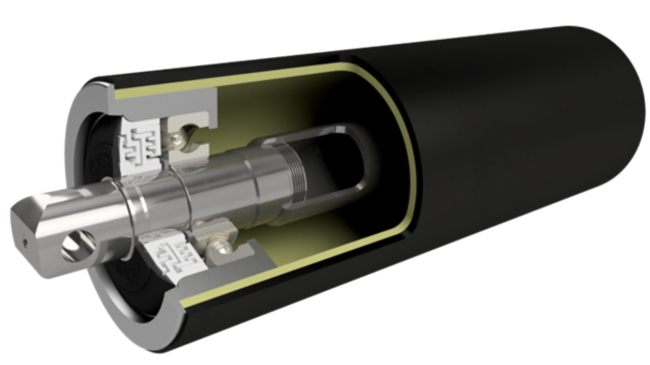

Our latest development in this area is called xForce.

This new generation of conveyor rollers has an roller tube made of glass fiber-reinforced plastic tube with PU coating, lightweight bearing housings and an bending resistant hollow axle. Such conveyor rollers are primarily used when the following requirements are placed on the conveyor rollers:

- Weight reduction (up to 40% lower total mass compared to steel rollers)

- High load capacity (50% higher load capacity compared to standard plastic conveyor rollers)

- Chemical resistance

- Heat resistance

- Low noise emission values

- Very good concentricity properties (TIR <0.2 mm/m)

- Long service life

- Self-cleaning properties (avoidance of caking)

- Anti-magnetic properties

xForce - tested in field tests

Thanks to their outstanding properties, these conveyor rollers have passed several years of field tests in Germany and Chile with flying colors.

In Germany, xForce was tested in a belt conveyor with a mass flow of 22,000 t/h at high conveying speeds (>10 m/s) and with relatively high loads per roller (up to 7.3 kN).

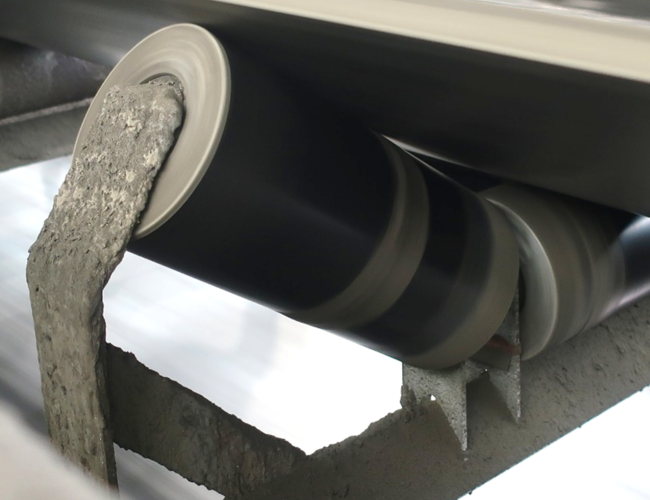

In Chile, xForce was used in a belt conveyor with a lower mass flow rate, but conveying a cohesive bulk material, which always caused caking on the conveyor roller tubes of conventional steel rollers.

This problem was successfully solved thanks to the use of xForce.

Your contact person

-

Idlers sales

-

+49 (2041) 177 - 227

-

Idlers and conveyor belt rollers

-

+49 (2041) 177 - 0