Metal active gas welding (MAG) has established itself as our standard welding process. It guarantees a high-quality, extremely durable connection between the roller tube and the bearing housing.

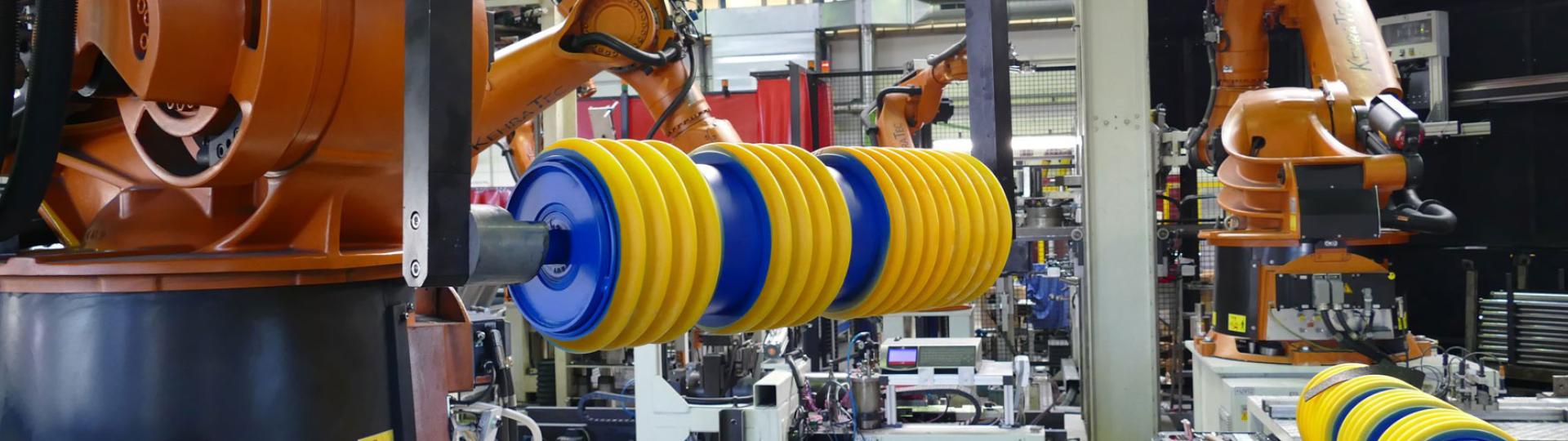

In our automated production line, four welding machines weld two tubes simultaneously on both sides in order to achieve a high throughput.

During the welding process, the voltage, current, wire speed and gas supply are constantly monitored automatically to guarantee 100% quality at this point too.

Our special solutions, which are always tailored to the needs of our customers, also use other welding processes: manual arc welding, metal inert gas welding (MIG) and tungsten inert gas welding (TIG).

Your contact person

-

Idlers sales

-

+49 (2041) 177 - 227

-

Idlers and conveyor belt rollers

-

+49 (2041) 177 - 0