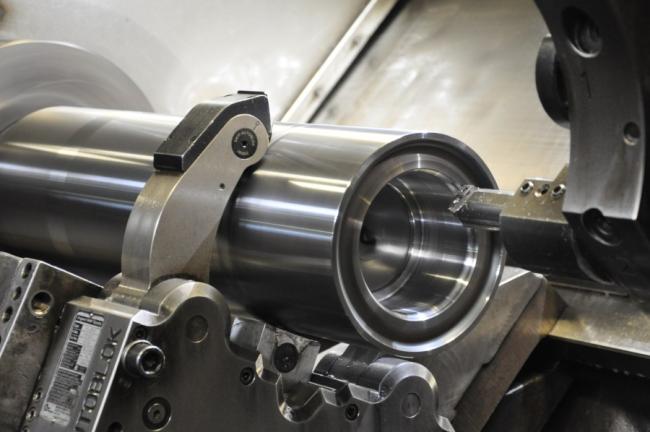

The basic components for our conveyor rollers, idlers and pulleys up to a diameter of 500 mm and a length of 4000 mm are manufactured here on high-precision CNC automatic lathes, turning and milling centers and other machining centers for milling and drilling.

We always machine the shafts and tubes in a single clamping operation. This ensures that the ball bearing seats of the shafts and the tubes respectively the tube assemblies of a later conveyor roller are preciselly aligned.

This geometric advantage is extremely important for the service life of an idler roller.

Your contact person

-

Idlers sales

-

+49 (2041) 177 - 227

-

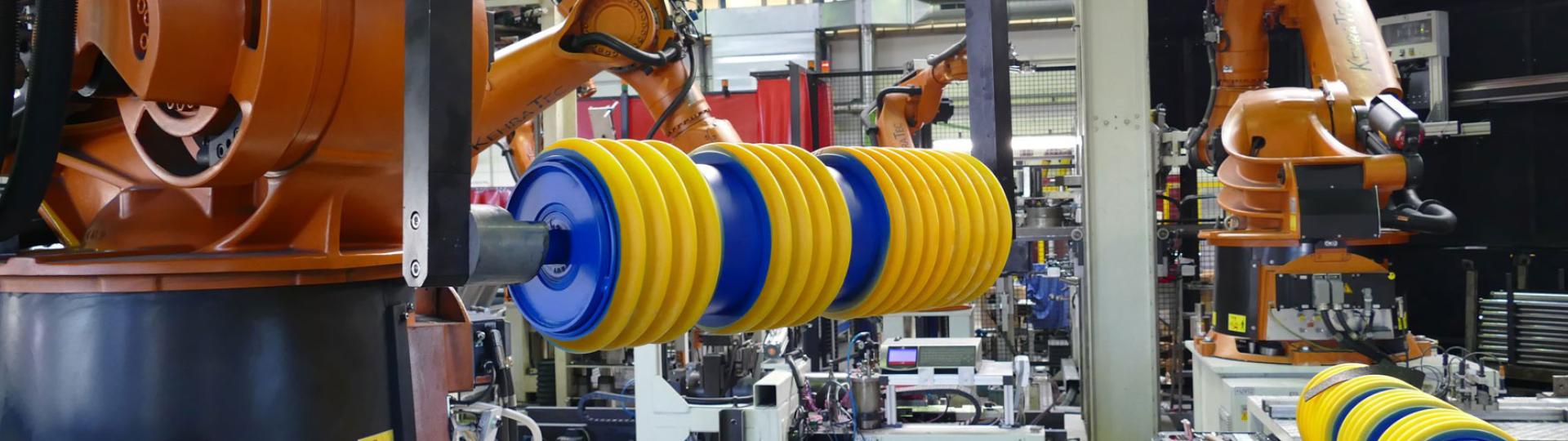

Idlers and conveyor belt rollers

-

+49 (2041) 177 - 0