PU support rings - exemplary design adaptation of the support rollers

Problem definition

In belt conveyors for bulk material handling, support rings are often used on the return rollers (conveyor rollers of the lower belt run) in order to adapt the rollers optimally to the operating conditions in the lower run.

The most important aim here is to protect against caking, which can otherwise occur on the non-elastic steel surface of the roller tube. The bulk material particles carried by the conveyor belt adhere to the running surface of the conveyor roller. The diameter of the conveyor roller increases and the shape becomes irregular (see photo). This can lead to the following problems:

- Irregular and therefore significantly faster wear of the conveyor rollers;

- Belt misalignment;

- Belt vibrations and thus vibrations and impact loads on the conveyor rollers, which can lead to bearing damages to the conveyor rollers;

- High noise emissions.

Solution

A lagging made of an elastic material is used for the running surfaces of the conveyor rollers. This prevents caking from forming on the running surfaces of the conveyor rollers.

The simplest way to implement this design is to use rings made of elastic material, which are installed at certain distances from each other on the roller tube - the support rings.

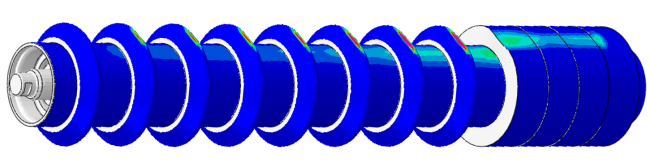

The types, number and positions of the support rings on the conveyor roller tube are defined by the "support ring arrangements".

This not only solves the problems mentioned above, but also achieves a number of other important properties:

- Protection against corrosion;

- Reduction of the resistance to movement of the belt (due to the rolling resistance);

- Damping of belt vibrations;

- Significant reduction in noise emissions of the idlers during conveyor operation;

- Reduction of the conveyor roller weight and in particular the rotating masses of the conveyor roller;

- Visualization of wear on the conveyor rollers running surfaces for quick and easy inspection, which is important to prevent unplanned downtimes due to weared rollers.

Wear visualization is a particularly important advantage compared to idlers without support rings. It is a very good design measure to effectively prevent wear-related idler shell breakages and the resulting belt damage (pizza cutter).

Rubber vs. polyurethane

In the past, only rubber support rings were used - mainly for cost reasons. We started using polyurethane support rings a long time ago. The reasons for this are as follows:

- Compared to standard rubber products under the same operating conditions, a service life extension by a factor of five;

- Material: KÜPPER special polyurethane compound, abrasion max. 20mm³ (DIN 53516);

- Reduction of running resistance by a factor of two compared to rubber support rings;

- Polyurethane is self-extinguishing;

- Less heat generation due to less flexing work in the material compared to rubber.

Designs

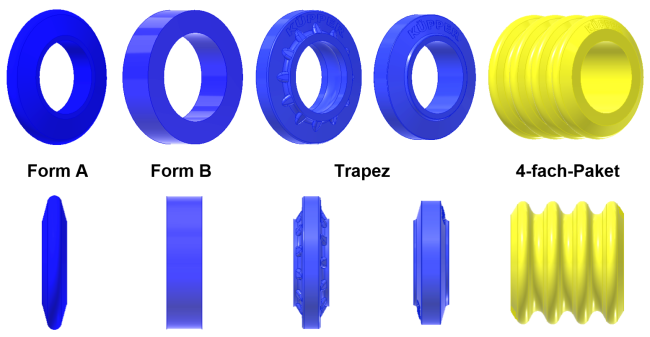

We mainly use support rings in three designs:

- Form A (acc. to DIN 15210);

- Form B (acc. to DIN 15210);

- Trapezoidal.

We have optimized the design of the latter especially for the highest demands. It has an improved geometry with reinforcing ribs and is mainly used for the production of "Compact Plus" and "Premium" quality class conveyor rollers.

We are also happy to offer you the 4-fold packages made of PU.

We look forward to your inquiry!

Your contact person

-

Idlers sales

-

+49 (2041) 177 - 227

-

Idlers and conveyor belt rollers

-

+49 (2041) 177 - 0