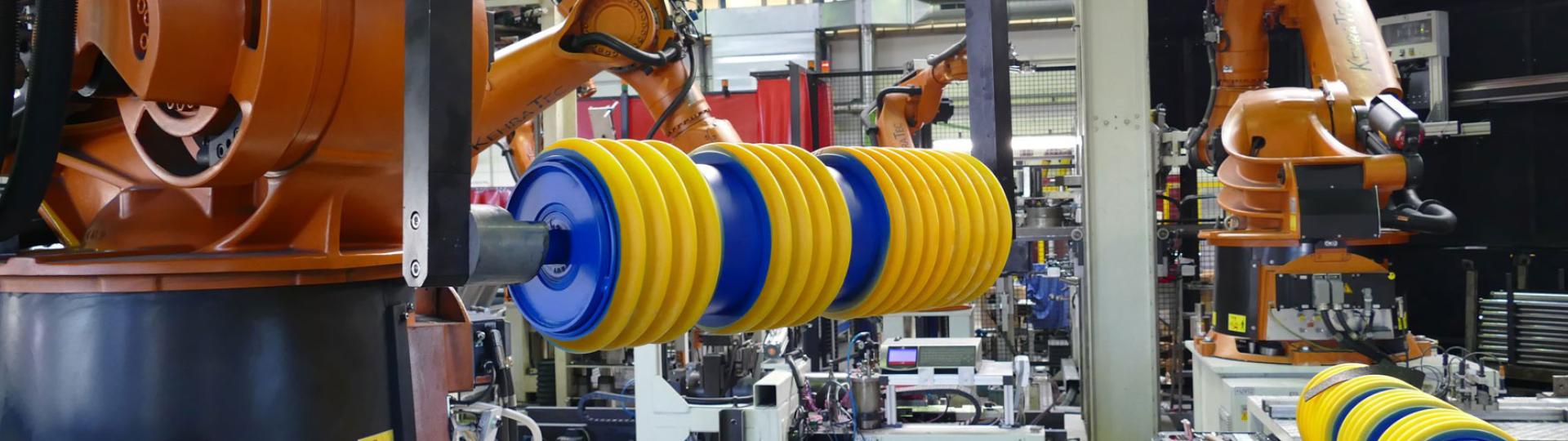

In order to maintain the quality achieved in the production of shafts and tube assemblies, we assemble our conveyor rollers on a fully automated assembling line.

Here, seven robots assemble the individual components of the idlers roller every minute. During assembling, all the quality parameters that are important for an conveyor roller are constantly monitored.

Axial play, concentricity and running resistance are checked for each roller. All this and other measurement results are recorded for each conveyor roller with allocation.

With our premium rollers, the unbalance is also determined. At the same time, the dust covers are fitted with the appropriate balancing weights in an integrated welding station. These dust covers are then pressed into the rollers in the correct position. The balancing result is then checked again and recorded.

Rubber or polyurethane rings are automatically pressed onto return rollers and then axially secured by welding on end rings.

Your contact person

-

Idlers sales

-

+49 (2041) 177 - 227

-

Idlers and conveyor belt rollers

-

+49 (2041) 177 - 0