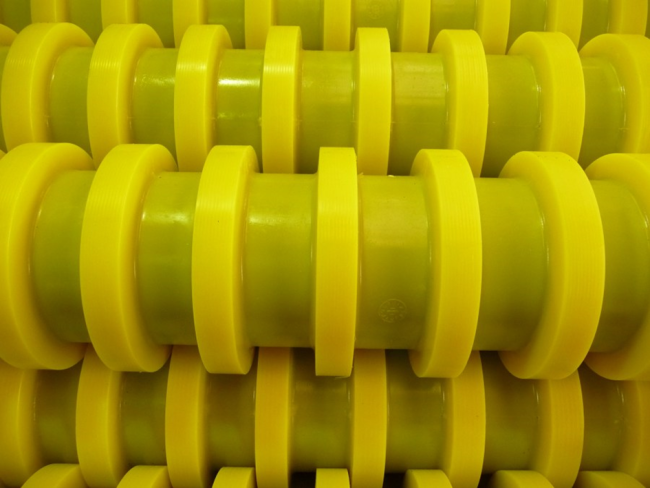

PU coated rollers

If the environment is particularly corrosive and the risk of caking is particularly high, if higher radial forces act on the idler, then we recommend using PU coated rollers. This rollers have a form of lagging that is casted onto the outer surface of the conveyor roller tube.

For maximum corrosion protection, up to 100% of the outer metallic surfaces of the rotating parts of the conveyor roller can be covered with polyurethane.

Overview of the advantages of the casted PU roller coating:

- Avoiding of caking on the roller tube and the related to this belt mistracking;

- Best possible protection against corrosion;

- Damping of belt vibrations;

- Reduction of noise emissions caused by conveyor rollers during the operation;

- Reduction of the conveyor roller weight

- Reduction of the rotating masses of the conveyor roller (up to 3x less energy required to accelerate the roller);

- Visualization of the wear of the conveyor roller running surfaces to simplify maintenance and avoid the unplanned downtimes due to weared rollers;

- Compared to standard rubber products, the service life is extended by a factor of five;

- Material specially optimized for the application: KÜPPER special compound, abrasion 20mm³ (acc to DIN 53516);

- Reduction of running resistance by a factor of two compared to rubber products;

- Polyurethane is self-extinguishing;

- Less heat generation due to less flexing work in the material compared to rubber;

- Improved emergency running properties compared to conveyor rollers with fitted support rings;

- Higher radial loads permitted than for rollers with support rings.

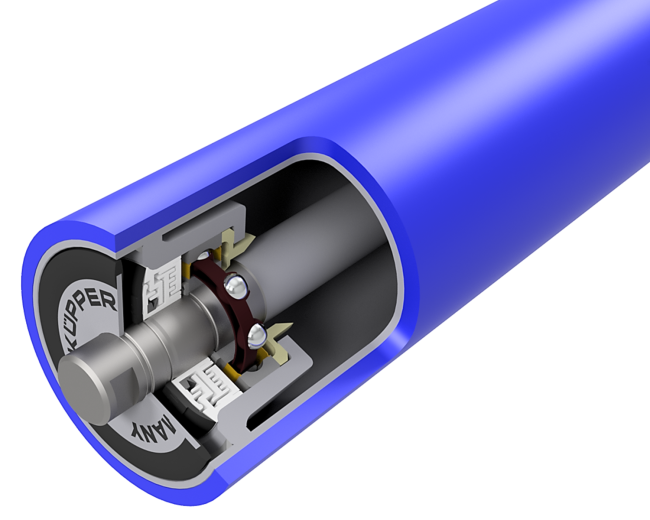

PU coating with support ring geometry

When used in the lower run of a belt conveyor, a conveyor roller with PU coating basically has all the advantages of a roller equipped with PU support rings. However, compared to the fitted support rings, the casted PU roller coating with support ring geometry can be subjected to even higher radial forces and also offers the best possible corrosion protection.

In addition, the casted support rings are not under tension and are firmly bonded to the surface of the roller tube. This increases the emergency running properties of the conveyor roller in the event of extremely advanced wear of the rings - the PU covering can be slowly weared almost completely without individual parts of it coming loose from the roller tube.

PU coating in cylindrical form

The PU coating in cylindrical form can be used in many applications for conveyor rollers. We recommend this when a high degree of corrosion protection or protection against caking is required. Or when the radial loads are too high to use support ring geometry.

It can also be used in the upper run of a belt conveyor in many cases. Depending on the application, we can use different PU mixtures with specific adaptation of the material properties.

Your contact person

-

Idlers sales

-

+49 (2041) 177 - 227

-

Idlers and conveyor belt rollers

-

+49 (2041) 177 - 0