Silent rollers - the important contribution to noise reduction

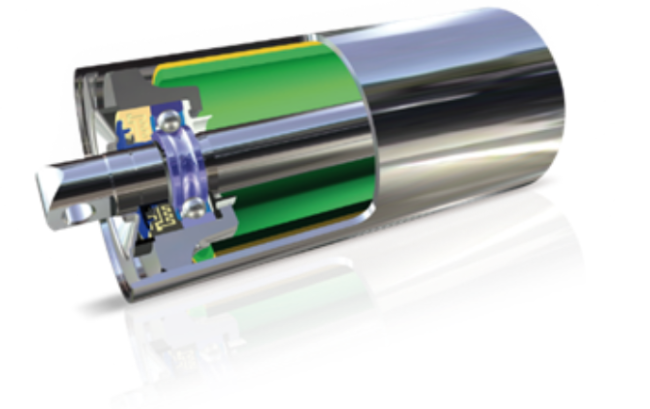

KÜPPER Silent rollers are noise-reduced conveyor rollers, i.e. rollers that are significantly quieter in operation than conventional standard conveyor rollers thanks to their special design.

What are the benefits of noise reduction measures?

Reducing the noise emissions of a conveyor is important because, among other things:

- Increases safety and productivity in the workplace;

- Reduces noise levels in nearby workplaces or places of residence;

- May make the operation of the conveyor legally permissible in the first place (see e.g. "TA Lärm" for Germany);

- Significantly facilitates inspections and maintenance of the systems;

- Improves working conditions;

- Reduces the impact on nature (particularly important for installations near nature conservation areas).

Noise is harmful to human health and the environment. For this reason, regulations and restrictions on noise emissions are becoming increasingly strict worldwide (see, for example, the Environmental Noise Directive (EU Directive 2002/49/EC)). At the same time, conveyor systems are becoming faster and more powerful. Increasing the conveying capacity of existing belt conveyors is often achieved by increasing their conveying speed. This leads to an increase in noise emissions.

Approval for the construction or operation of belt conveyors, particularly in the vicinity of residential or nature conservation areas, depends, among other things, on whether the conveyors comply with the locally applicable noise emission limits.

What can we do?

The most effective way to reduce noise pollution is to identify the source of the noise and take measures to reduce noise at the source. One of the sources of noise on the belt conveyors are the idler rollers. The most important factors that influence the sound power level of the conveyor rollers are

- Conveying speed,

- Surface condition of the conveyor belt (adhesion of the material, belt joints, surface damages),

- Shape accuracy of the conveyor rollers (due to manufacturing accuracy and contamination during operation, e.g. caking on the running surfaces),

- Structural design of the conveyor rollers.

As a roller manufacturer, we can influence the latter two factors. This is how we have developed our low-noise KÜPPER Silent rollers: high precision in manufacturing combined with suitable design adjustments to dampen the vibrations of the conveyor roller parts.

What were we able to achieve?

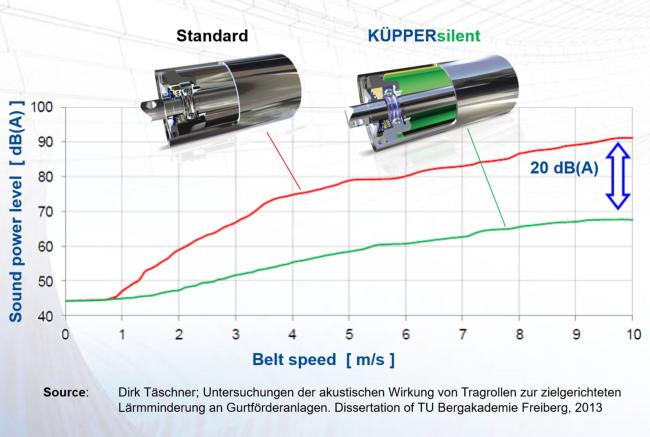

Numerous laboratory tests and field tests carried out by us, by the BTU Cottbus-Senftenberg and by TÜV Nord have shown that the use of low-noise KÜPPER Silent rollers in belt conveyors enables a reduction in the sound power level of over 20dB(A) under normal operating conditions.

Such a reduction in noise level is perceived as a 75% reduction in volume!

Tests and measurements have shown that our KÜPPER Silent rollers produce less noise than plastic conveyor rollers. However, they have a much longer service life and can withstand much greater loads.

For bulk goods and unit loads!

Thanks to appropriate design measures, we can offer you almost all of our conveyor rollers and pulleys in a noise-reduced design - both for bulk material handling and for unit loads. We harmonize environment and technology!

Your contact person

-

Idlers sales

-

+49 (2041) 177 - 227

-

Idlers and conveyor belt rollers

-

+49 (2041) 177 - 0