Carry Rollers

The term Carry Rollers or Carrying Rollers refers to the idler rollers that are installed in the upper run of the belt conveyor and carry the conveyor belt and the bulk material lying on the belt.

Because they are part of a belt conveyor, all idler rollers are often referred to collectively as " belt conveyor rollers ". The carry roller is therefore a type of conveyor belt rollers.

Detailed information on the dimensions of the rollers can be found in the chapter "Dimensions and designs".

Quality classes of carry rollers in comparison

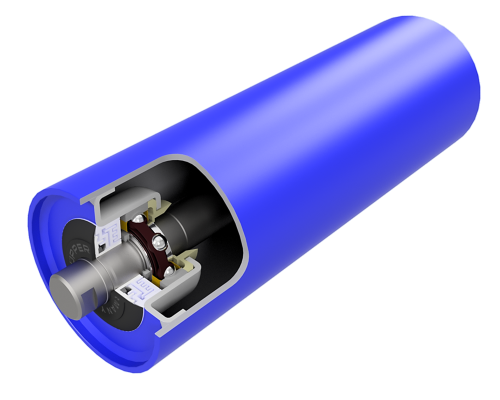

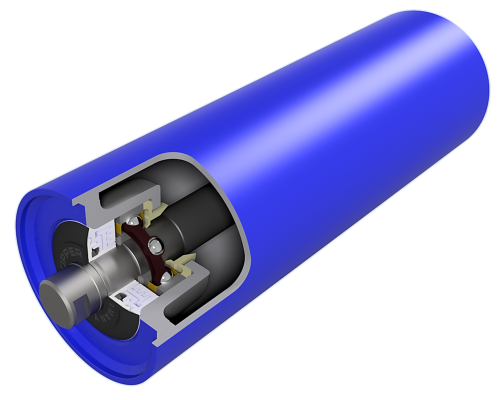

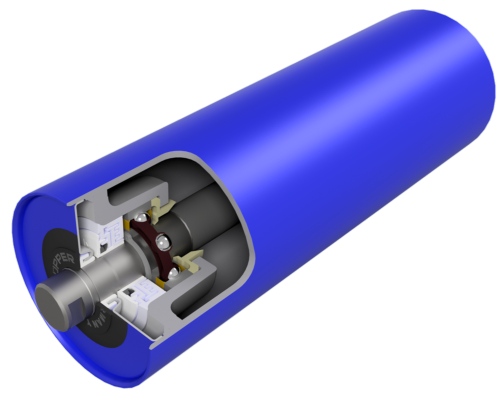

We have defined three quality classes ("Compact", "Compact Plus" and "Premium"), which we recommend as the optimum solution depending on the specific application. Each quality class corresponds to the type of operating conditions on site and the requirements on the idler rollers.

If noise reduction is required, we can offer you all idlers in "silent" design.

More detailed information can be found in the sub-chapters on the respective quality classes (see below).

| Quality class |

|

|

| |

Roller tube | ||||

| Tubes | Welded cold-sized steel tubes acc. to EN 10305-3 | Welded cold-sized steel tubes acc. to EN 10305-3; with restricted tolerances (Küpper Standard) | Welded cold-sized steel tubes acc. to EN 10305-3; with restricted tolerances (Küpper Standard) | |

| Materials | S235JR acc. to EN 10025-2 | S235JR acc. to EN 10025-2 | S235JR acc. to EN 10025-2 | |

Bearing housing | ||||

| Type | Deep-drawn part | Forged part, cast part | Forged part | |

| Materials | DD13 acc. to EN 10111 | C15 acc. to EN 10267-2 or S235JR acc. to EN 10025-2 or EN-GJL-200 acc. to EN 1561 | C15 acc. to EN 10267-2 or S235JR acc. to EN 10025-2 | |

| Bearing seat | IT7 | IT7 | IT7 | |

Shaft | ||||

| Type | Solid | Solid or bending-resistant hollow shaft | Solid or bending-resistant hollow shaft | |

| Materials | Round bar steel acc. to EN 10277 | Round bar steel acc. to EN 10083-2 / Tube acc. to EN 10305-3 | Round bar steel acc. to EN 10083-2 / Tube acc. to EN 10305-3 | |

| Bearing seat | IT9 | IT6 | IT6 | |

Bearing | ||||

| Manufacturer | AKT | AKT | AKT | |

| Type of bearing | Deep-groove ball bearings | Deep-groove ball bearings | Deep-groove ball bearings | Spherical roller bearings |

| Bearing sizes | 6204 - 6306 | 6306 - 6312 | 6306 - 6312 | 21310 - 22312 |

| Sealing | 2Z | 2Z | 2Z | - |

| Radial bearing clearance | C4 | C4 | C4H | C3 |

| Tolerance class | P0 | P0 | P5 | P0 |

| Cage | Plastic cage | Plastic cage | Plastic cage | Sheet steel cage or brass cage |

| Lubrication | 50 - 60% of bearing´s free internal volume | 50 - 60% of bearing´s free internal volume | Customized solutions | |

Sealing | ||||

| Seal type | QLR hybrid seal | QLR hybrid seal | QLR hybrid seal Dust cover Roller protector | |

Running characteristics | ||||

| Total Indicated Runout (TIR) [mm/m] | 0,7* | 0,5* | ≤ 0,2 | |

| Balancing quality | ≤ G40 acc. to ISO 1940** | ≤ G25 acc. to ISO 1940** | ≤ G14 acc. to ISO 1940*** | |

* | Average value of the total delivery | |||

** | Belt speed 3 m/s | |||

*** | Belt speed up to 10 m/s | |||

Your contact person

-

Idlers sales

-

+49 (2041) 177 - 227

-

Idlers and conveyor belt rollers

-

+49 (2041) 177 - 0