Impact rollers

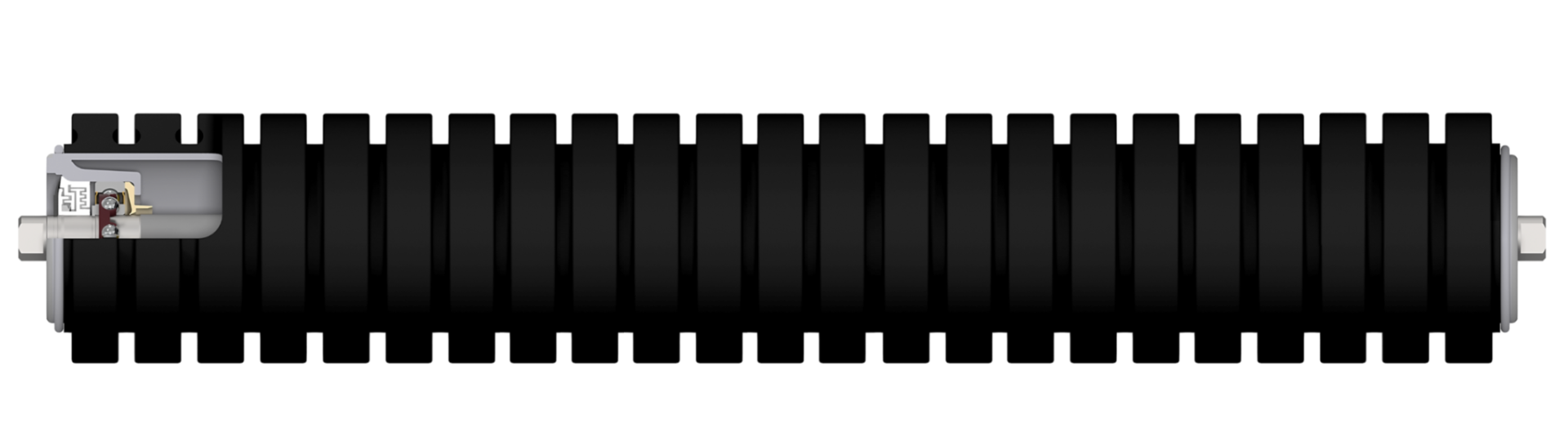

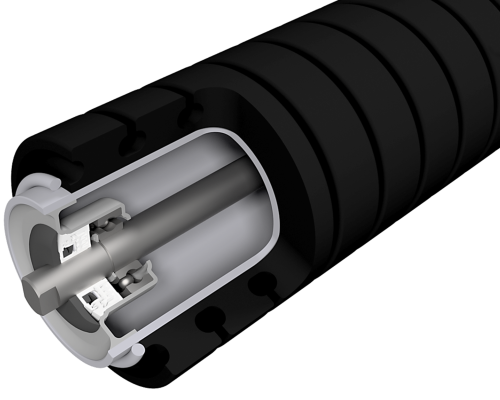

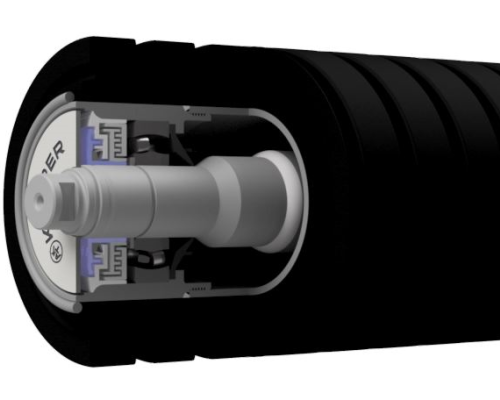

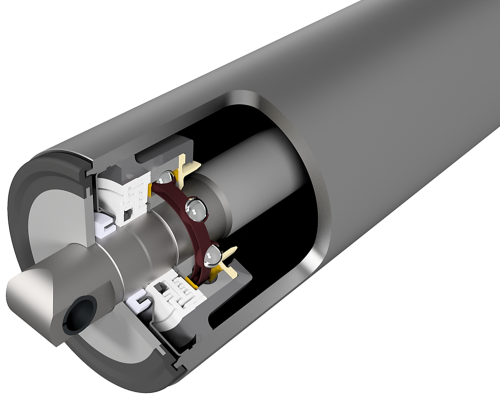

"Impact rollers" are the idler rollers installed in a belt conveyor in the area where the bulk material is fed onto the conveyor belt.

These rollers are generally subject to high loads: they not only carry the conveyor belt and the bulk material, but also absorb the forces of the impact of the bulk material on the conveyor belt.

To dampen the impact forces, the impact rollers are usually equipped with impact rings made from rubber. The impact rings are often also called buffer rings.

If the loads are particularly high, a hot-vulcanized rubber coating is used instead of the impact rings.

In the case of extremely high loads (e.g. individual lumps weighing up to 1 t at a feed drop height of >5 m), even the highest quality rubber coating cannot withstand the impact forces for long time without additional constructive measures to dampen them. In extreme cases, it is therefore better to dispense with any kind of rubber coating on the impact rollers and at the same time take other constructive measures to dampen the impact forces (see feed garlands, heavy-duty feed garlands).

Detailed information on the dimensions of the rollers can be found in the chapter "Dimensions and designs".

Comparison of quality classes of impact rollers

We have defined three quality classes ("Compact", "Compact Plus" and "Premium"), which we recommend as the optimum solution depending on the specific application. Each quality class corresponds to the type of operating conditions on site and the requirements on the rollers.

|

|

|

| ||

Roller tube | ||||

| Tubes | Welded cold-sized steel tubes acc. to EN 10305-3 | Welded cold-sized steel tubes acc. to EN 10305-3; with restricted tolerances (Küpper Standard) | Welded cold-sized steel tubes acc. to EN 10305-3; with restricted tolerances (Küpper Standard) | |

| Material | Steel S235JR acc. to EN 10025-2 | Steel S235JR acc. to EN 10025-2 | Steel S235JR acc. to EN 10025-2 | |

Bearing housing | ||||

| Type | Deep-drawn part | Forged part | Forged part | |

| Materials | Steel DD13 acc. to EN 10111 | Steel C15 acc. to EN 10267-2 or S235JR acc. to EN 10025-2 | Steel C15 according to EN 10267-2 or S235JR according to EN 10025-2 | |

| Bearing seat | IT7 | IT7 | IT7 | |

Shaft | ||||

| Type | Solid shaft | Solid or bending-resistant hollow shaft | Solid or bending-resistant hollow shaft | |

| Materials | Round bar steel acc. to EN 10277 | Round bar steel acc. to EN 10083-2 / Tube acc. to EN 10305-3 | Round bar steel acc. to EN 10083-2 / Tube acc. to EN 10305-3 | |

| Bearing seat | IT9 | IT6 | IT6 | |

Bearing | ||||

| Make | AKT | AKT | AKT | |

| Bearing type | Deep-groove ball bearing | Deep-groove ball bearing | Deep-groove ball bearing | Spherical roller bearings |

| Bearing sizes | 6204 - 6305 | 6306 - 6312 | 6310 - 6318 | 21310 - 22318 |

| Sealing | 2Z | 2Z | 2Z | - |

| Bearing clearance | C4 | C4 | C4H | C3 |

| Tolerance classes | P0 | P0 | P5 | P0 |

| Cage | Plastic cage | Plastic cage | Plastic cage | Sheet steel cage or brass cage |

| Greasing | 50 - 60% of bearing´s free internal volume | 50 - 60% of bearing´s free internal volume | Customized solutions | |

Seal | ||||

| Seal type | QLR hybrid seal | QLR hybrid seal | Weather shield | |

Running characteristics | ||||

| Total Indicated Runout (TIR) [mm/m] | - | - | ≤ 0,2 | |

Impact rings / coating | ||||

| Type | Impact rings or hot-vulcanized rubber coating | Impact rings or hot vulcanized rubber coating | - | |

| Material | Rubber | Rubber | - | |

Your contact person

-

Idlers sales

-

+49 (2041) 177 - 227

-

Idlers and conveyor belt rollers

-

+49 (2041) 177 - 0