Wood processing industry

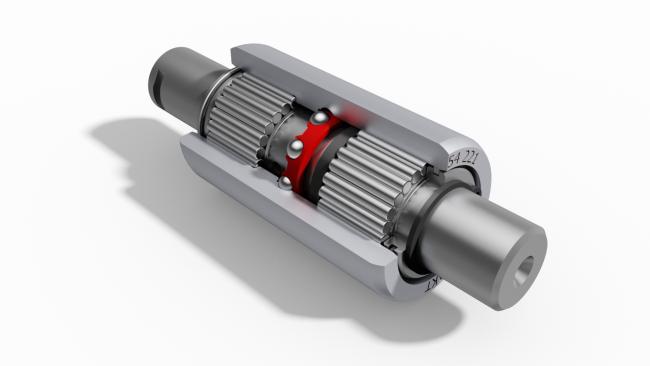

The wood processing industry presents plenty of different challenges for idlers and rolling bearings: while extreme robustness is required above all in timber harvesting and in the primary machining processes, and many impact loads are to be expected, the requirements for running accuracies and precision increase in further processing.

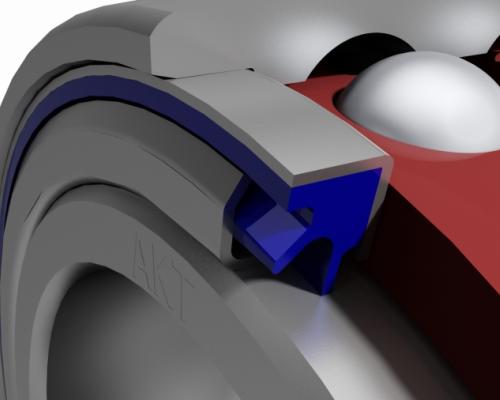

Common to the entire processing chain is the large amount of contamination with which the seals of the idlers and rolling bearings are confronted. These contaminants often contain a particularly high wood fiber content, can retain and swell water, and may also contain resins or be corrosive.

Thanks to our expertise in the development and manufacture of idlers, track rollers and rolling bearings, our products effectively overcome the challenges and thus increase the availability and performance of your machinery and equipment.

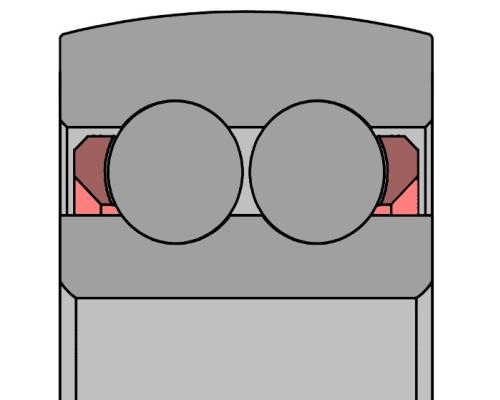

Durable Roller Bearings for Wood Processing

In the wood processing industry, large amounts of dust and contaminants often accumulate, becoming a challenge to seal the track rollers. Our AKT rolling bearings are installed in the machines of well-known manufacturers. The resulting synergy is continuously used to optimize the seals and the running accuracies of the track rollers. This ensures flawless operation, high running accuracy and optimum results for users.