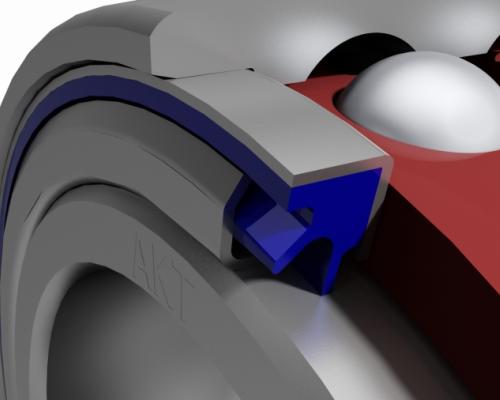

Our rolling bearings, track rollers and idlers for the field of automation, handling technology or robotics must meet a high degree of accuracy while providing the highest level of reliability and safety for our customers. The selection of the right lubricants and suitable load-bearing materials for the components of rolling bearings and track rollers plays a major role here. Through the continuous development of our products and our extensive experience, we can meet these requirements.